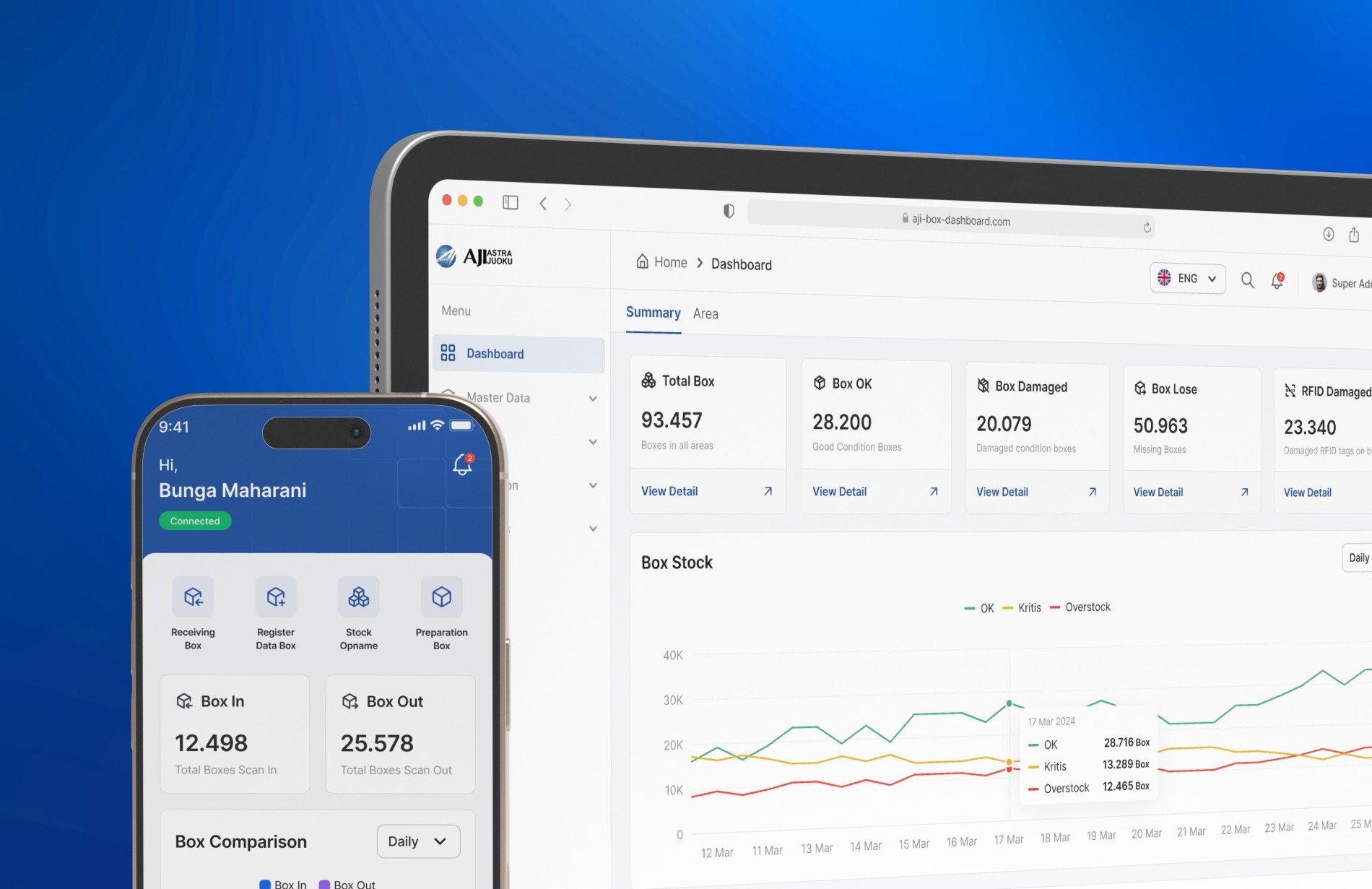

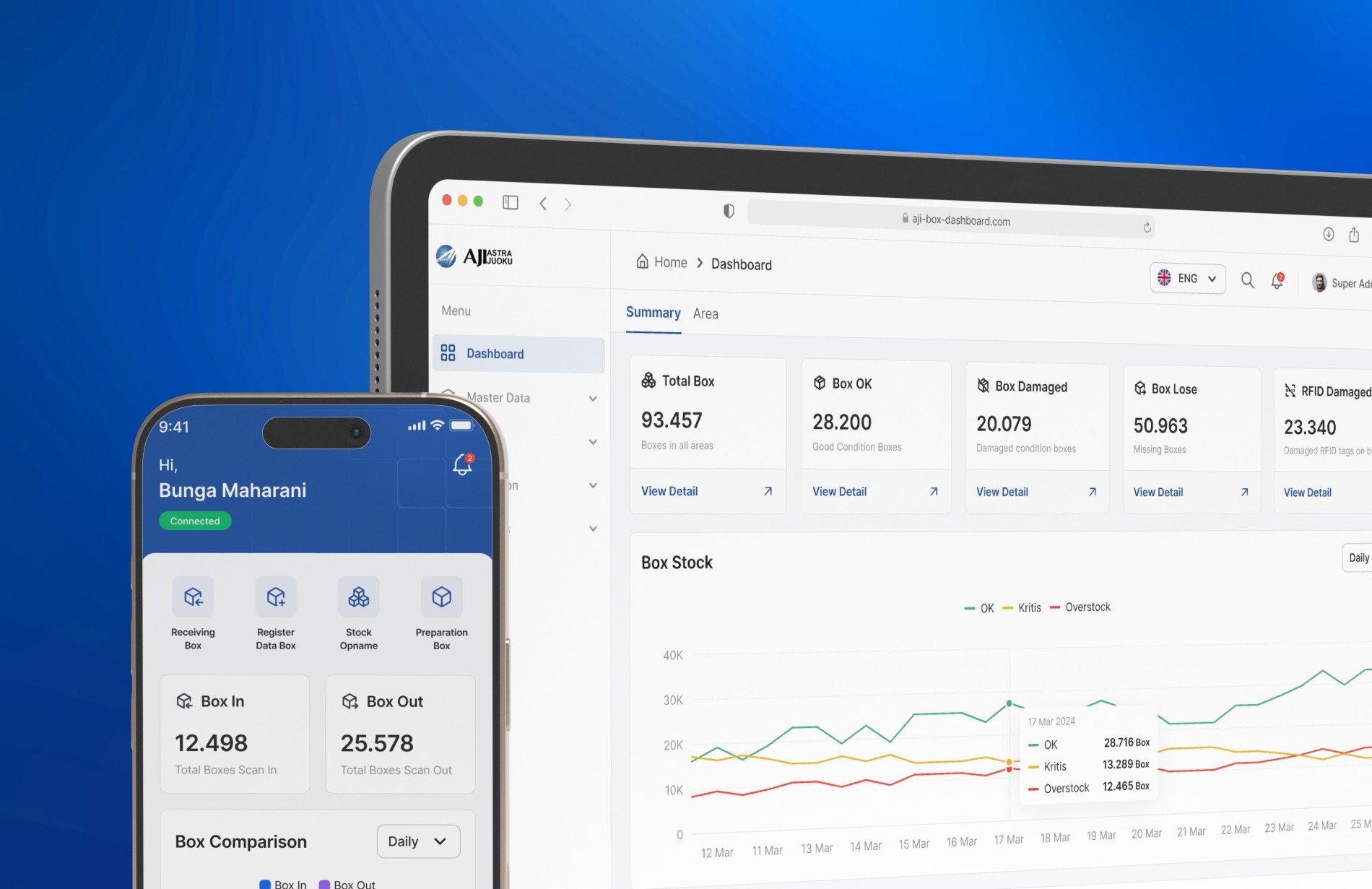

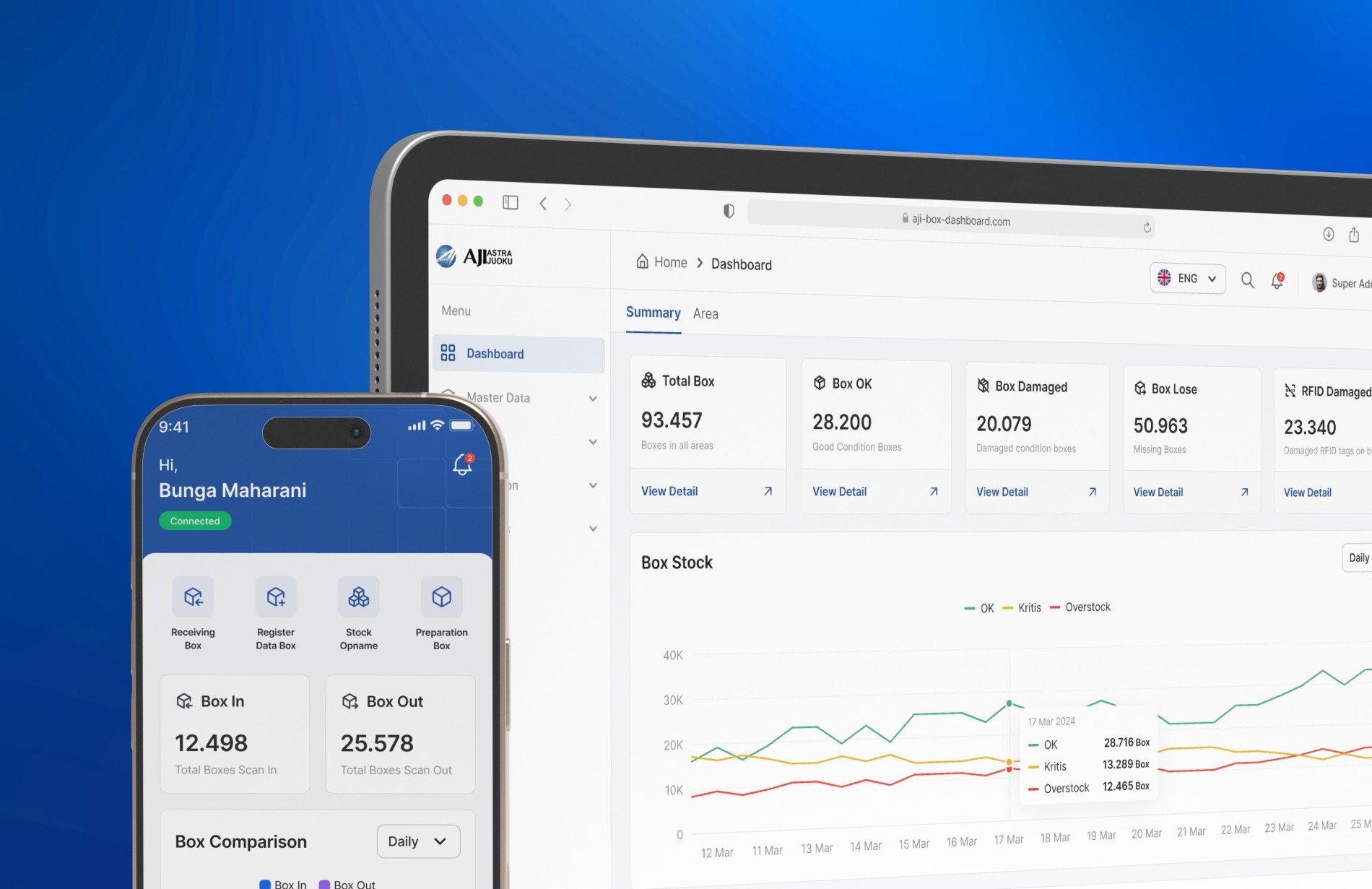

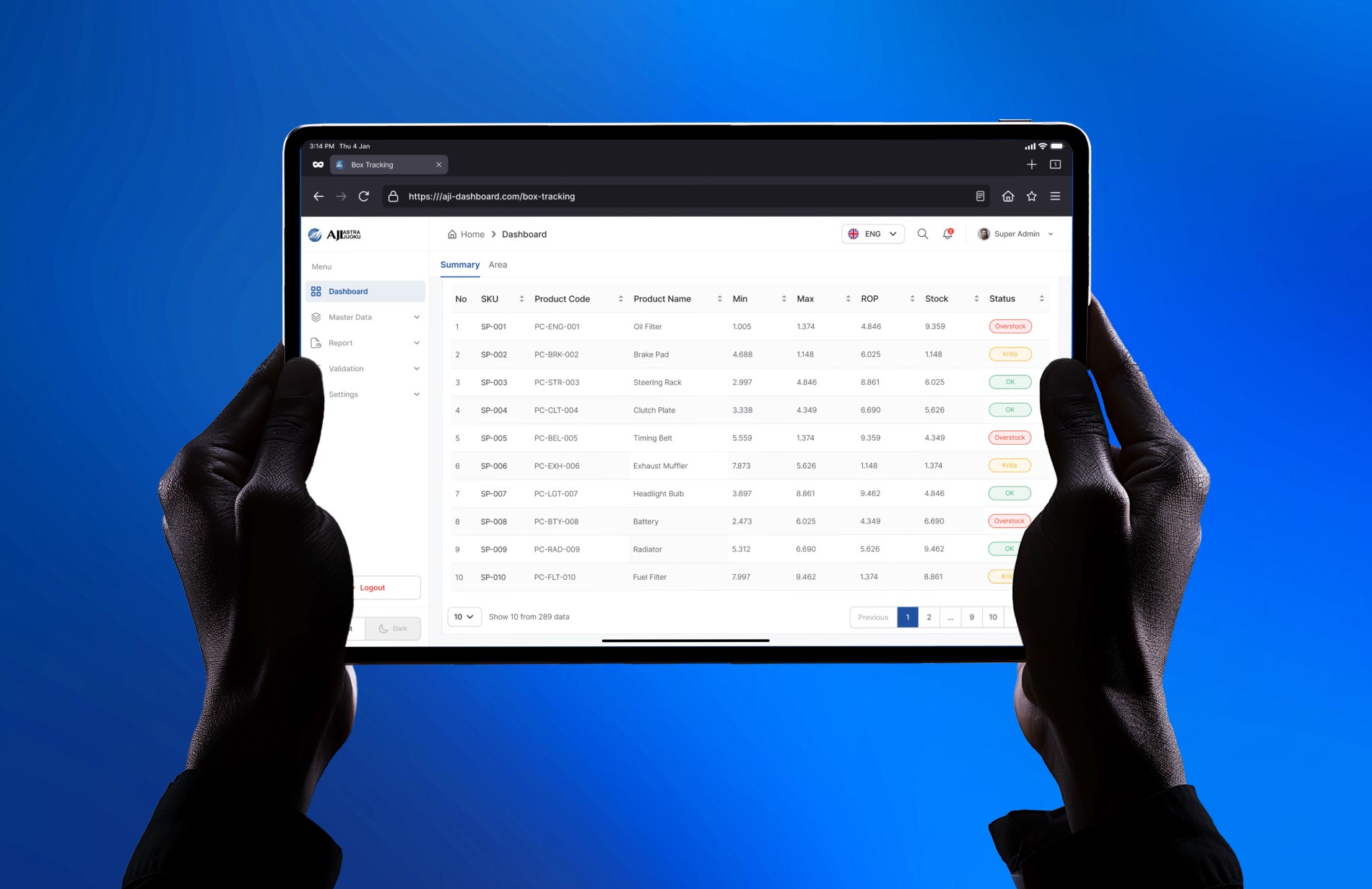

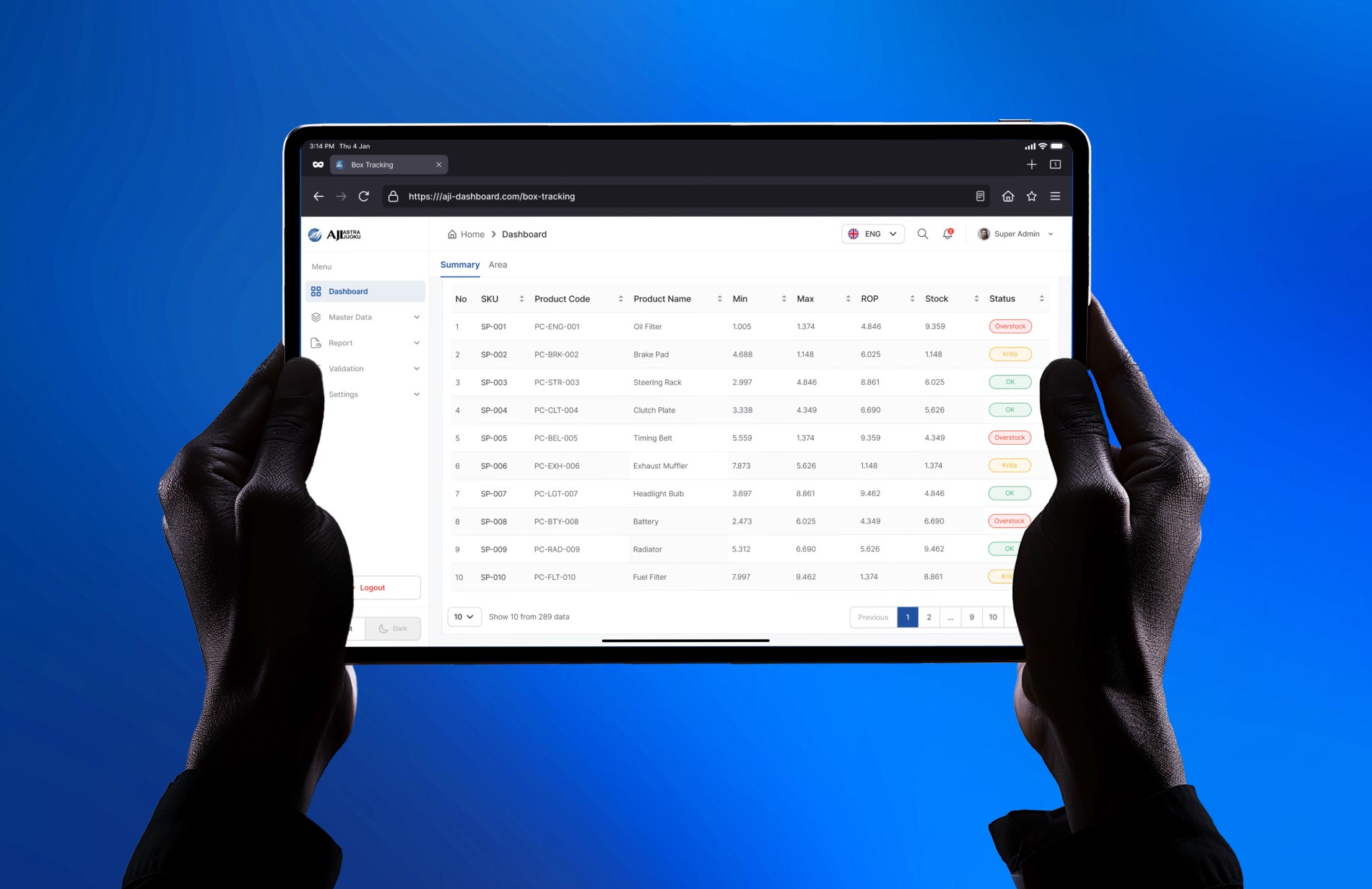

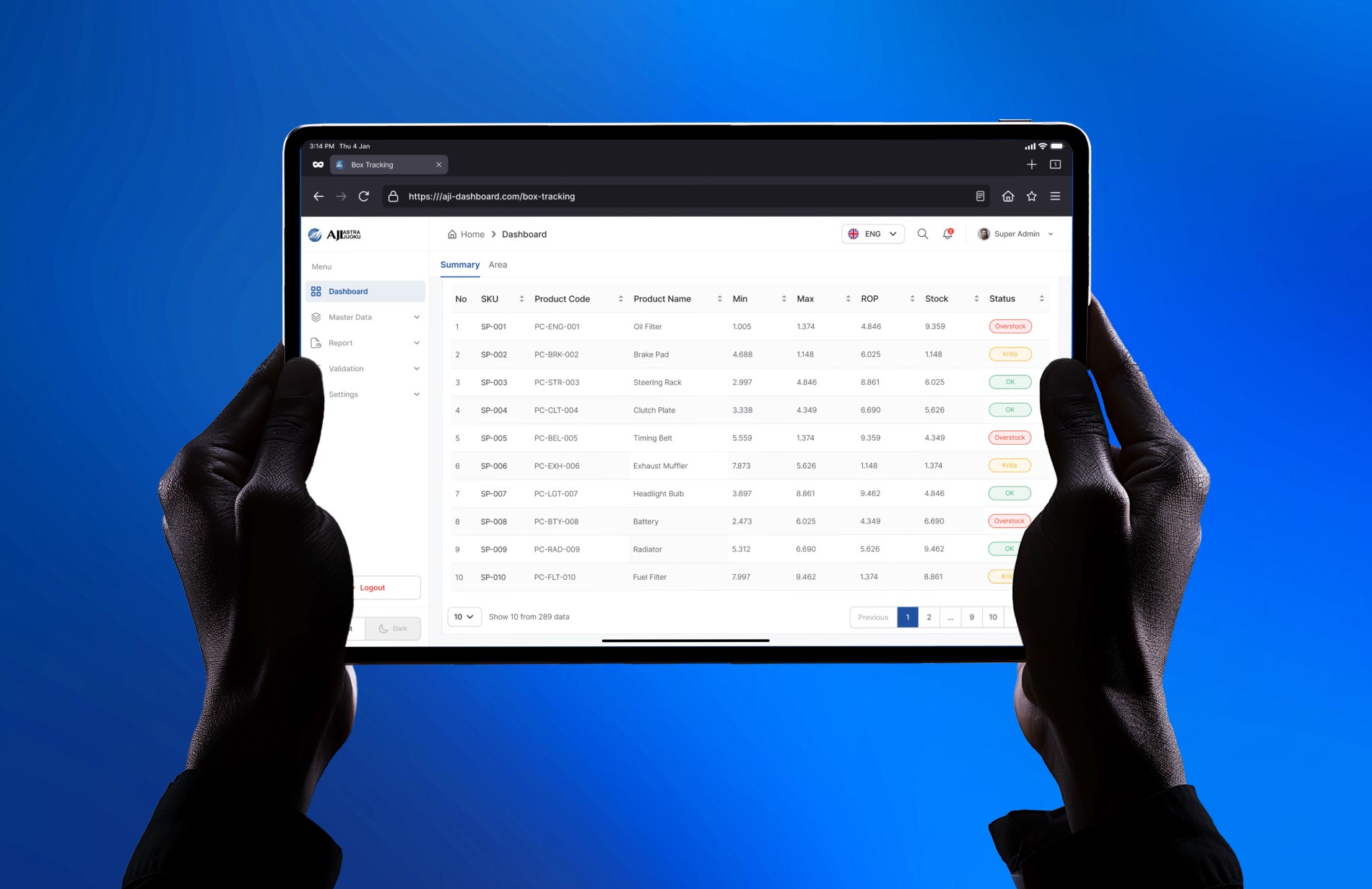

Dashboard

Dashboard

Operational UX

Operational UX

Process Optimization

Process Optimization

Enhanced Box Management System for Factory Workflow Improvement

Enhanced Box Management System for Factory Workflow Improvement

Enhanced Box Management System for Factory Workflow Improvement

Project Timeline

2024

2024

Industry

Manufacture

Manufacture

Client

Astra Juoku Indonesia

Astra Juoku Indonesia

Optimizing factory operations with a clearer, more reliable box management system that streamlines tracking and gives teams real-time visibility to keep production moving efficiently.

Optimizing factory operations with a clearer, more reliable box management system that streamlines tracking and gives teams real-time visibility to keep production moving efficiently.

PT. Astra Juoku Indonesia is implementing an RFID Box Tracking System to improve visibility and accuracy in its inventory operations. The initiative addresses challenges in locating boxes, maintaining reliable stock information, and managing movement across production and warehouse areas. With RFID as the core technology, the system reduces manual errors and supports faster, more reliable tracking.

PT. Astra Juoku Indonesia is implementing an RFID Box Tracking System to improve visibility and accuracy in its inventory operations. The initiative addresses challenges in locating boxes, maintaining reliable stock information, and managing movement across production and warehouse areas. With RFID as the core technology, the system reduces manual errors and supports faster, more reliable tracking.

To enable this shift, the project introduces an integrated web and mobile platform that delivers real-time box status, location history, and essential operational workflows. This transition moves the organization toward a more data-driven ecosystem, improving coordination between teams and creating a stronger foundation for efficient and scalable inventory management.

To enable this shift, the project introduces an integrated web and mobile platform that delivers real-time box status, location history, and essential operational workflows. This transition moves the organization toward a more data-driven ecosystem, improving coordination between teams and creating a stronger foundation for efficient and scalable inventory management.

Challenge & Approach

Challenge & Approach

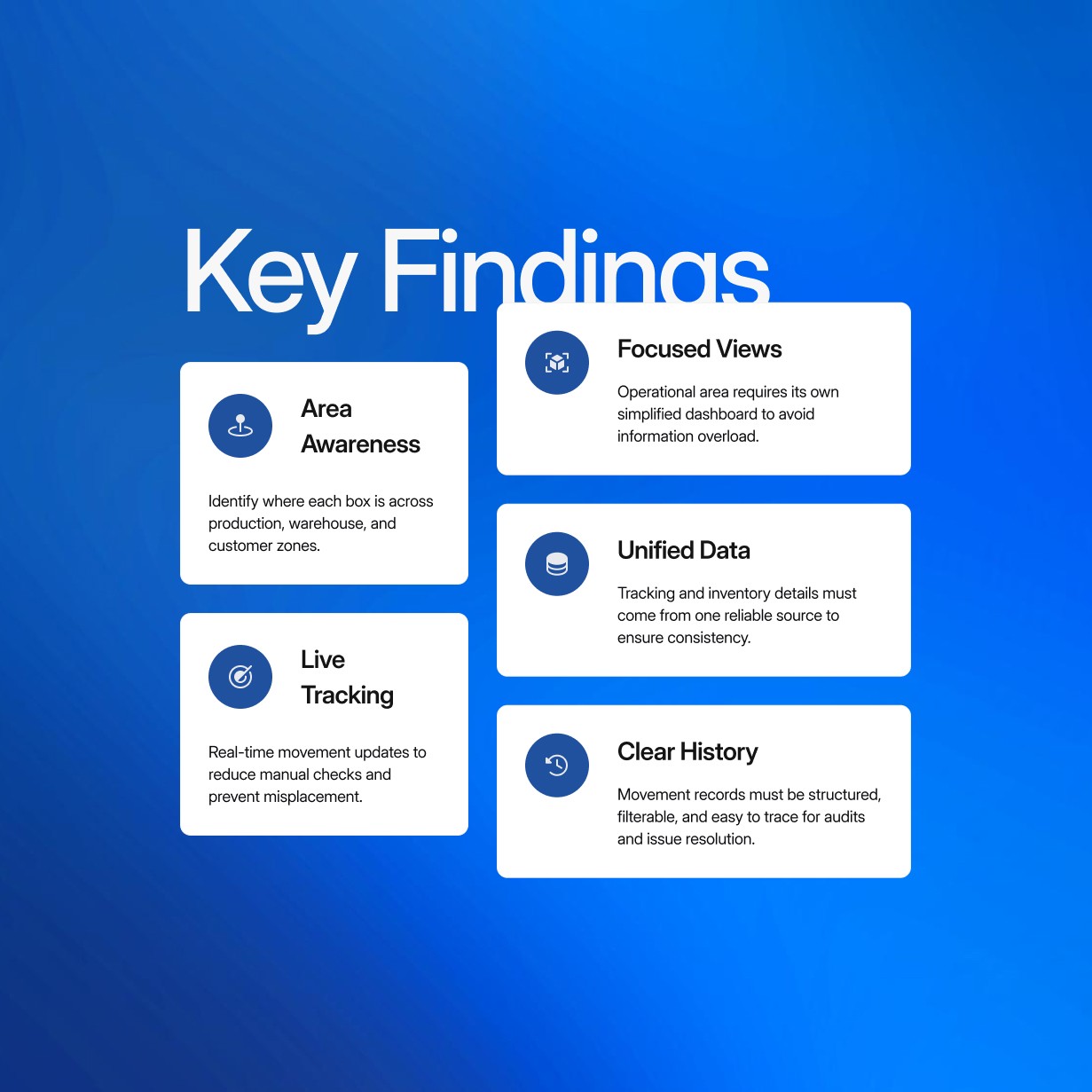

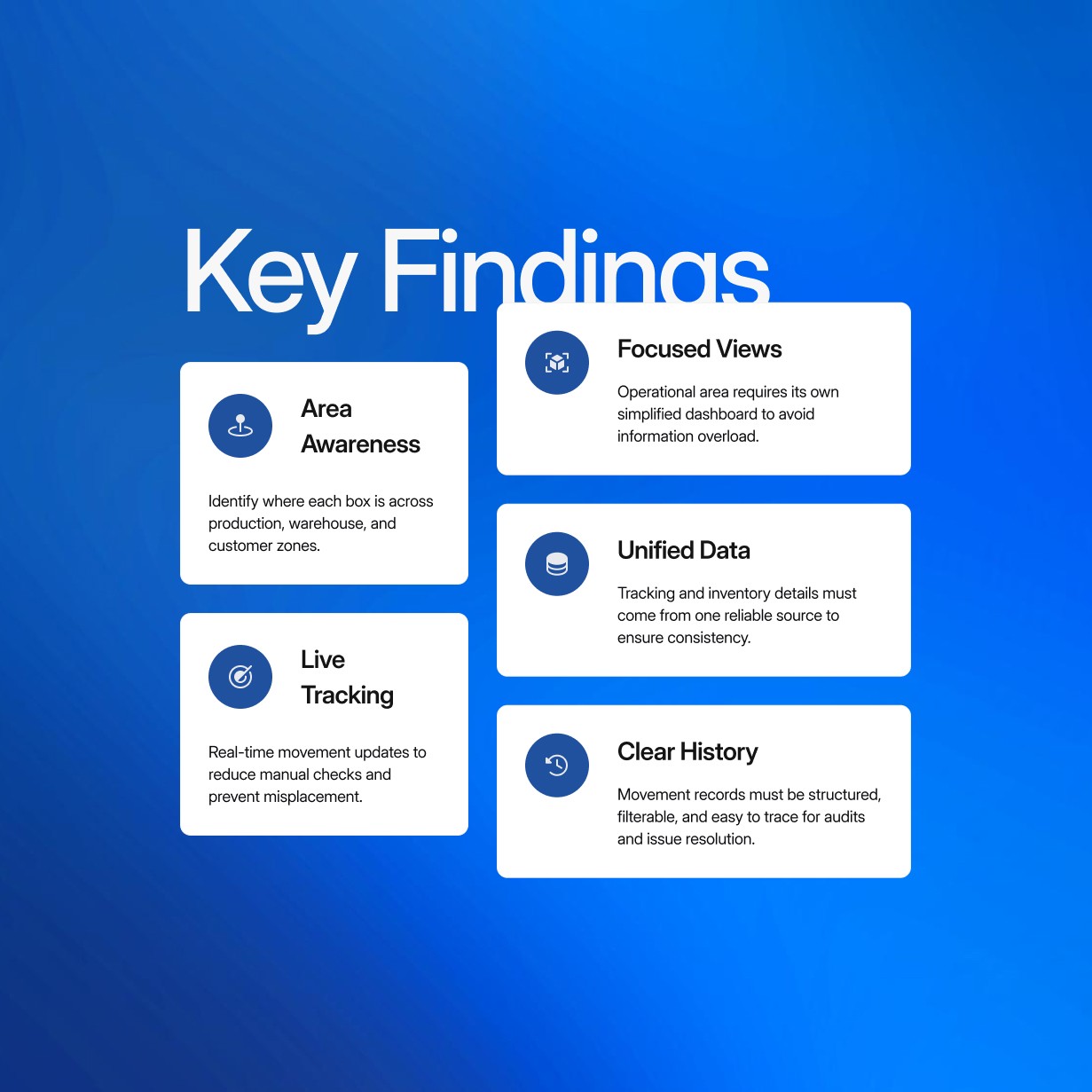

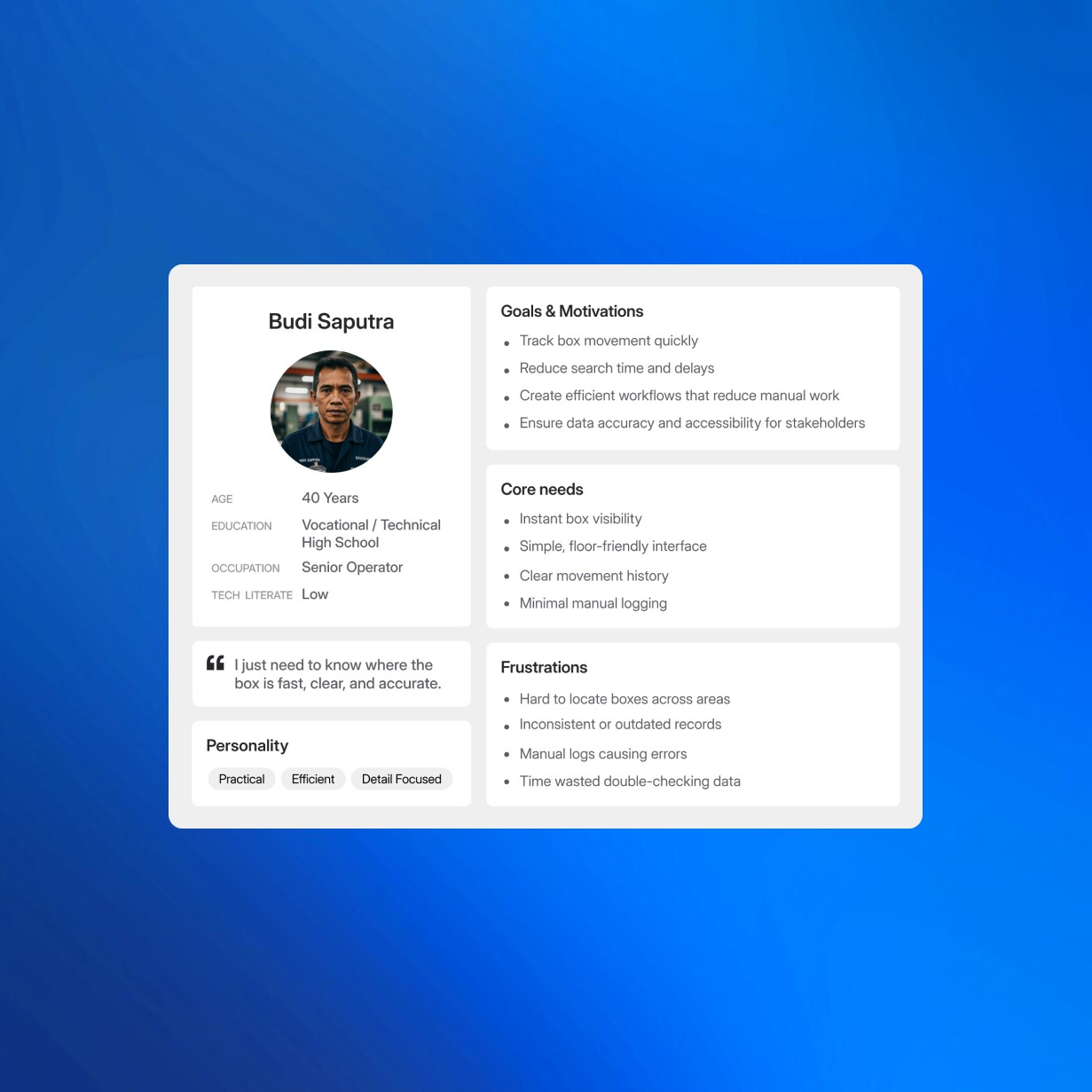

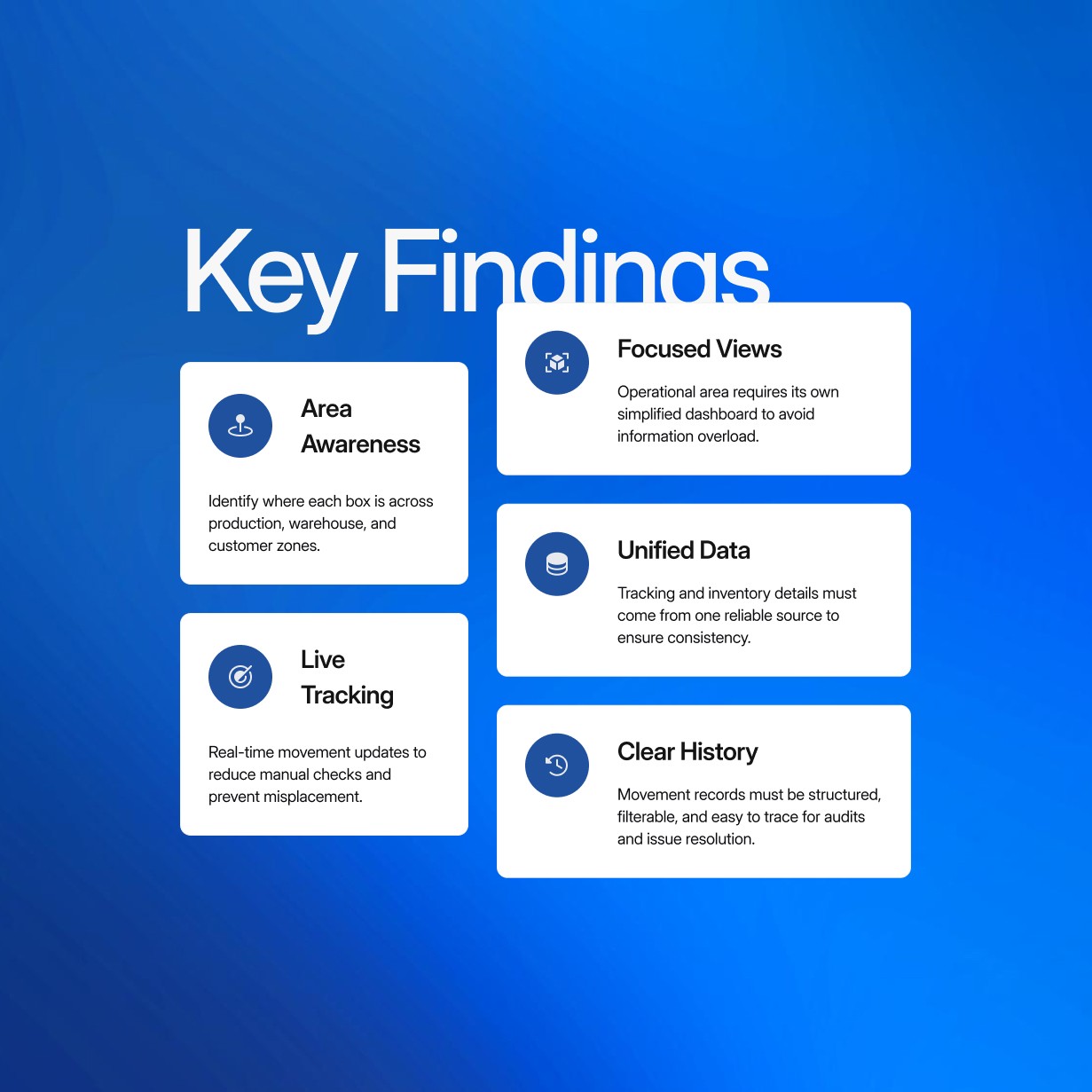

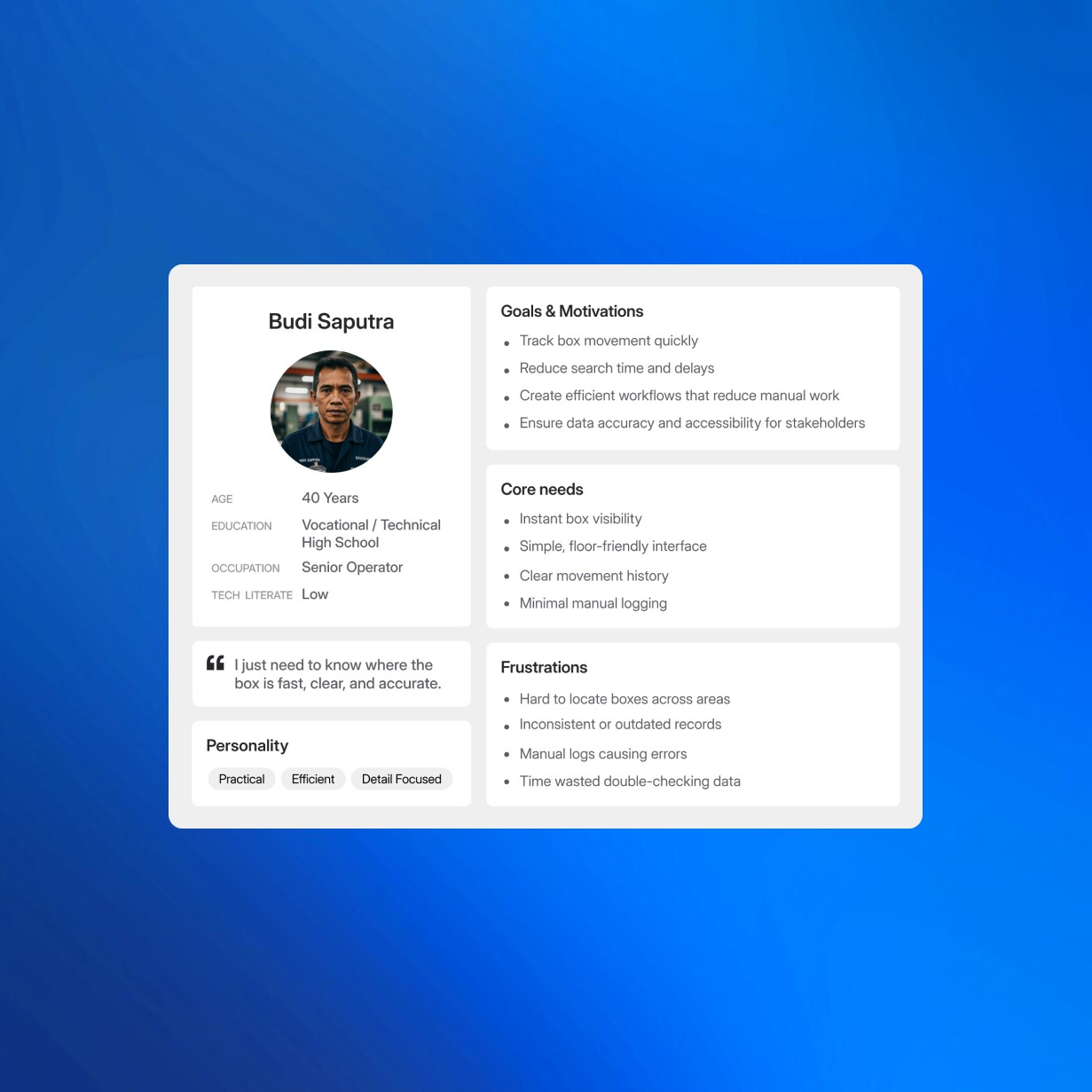

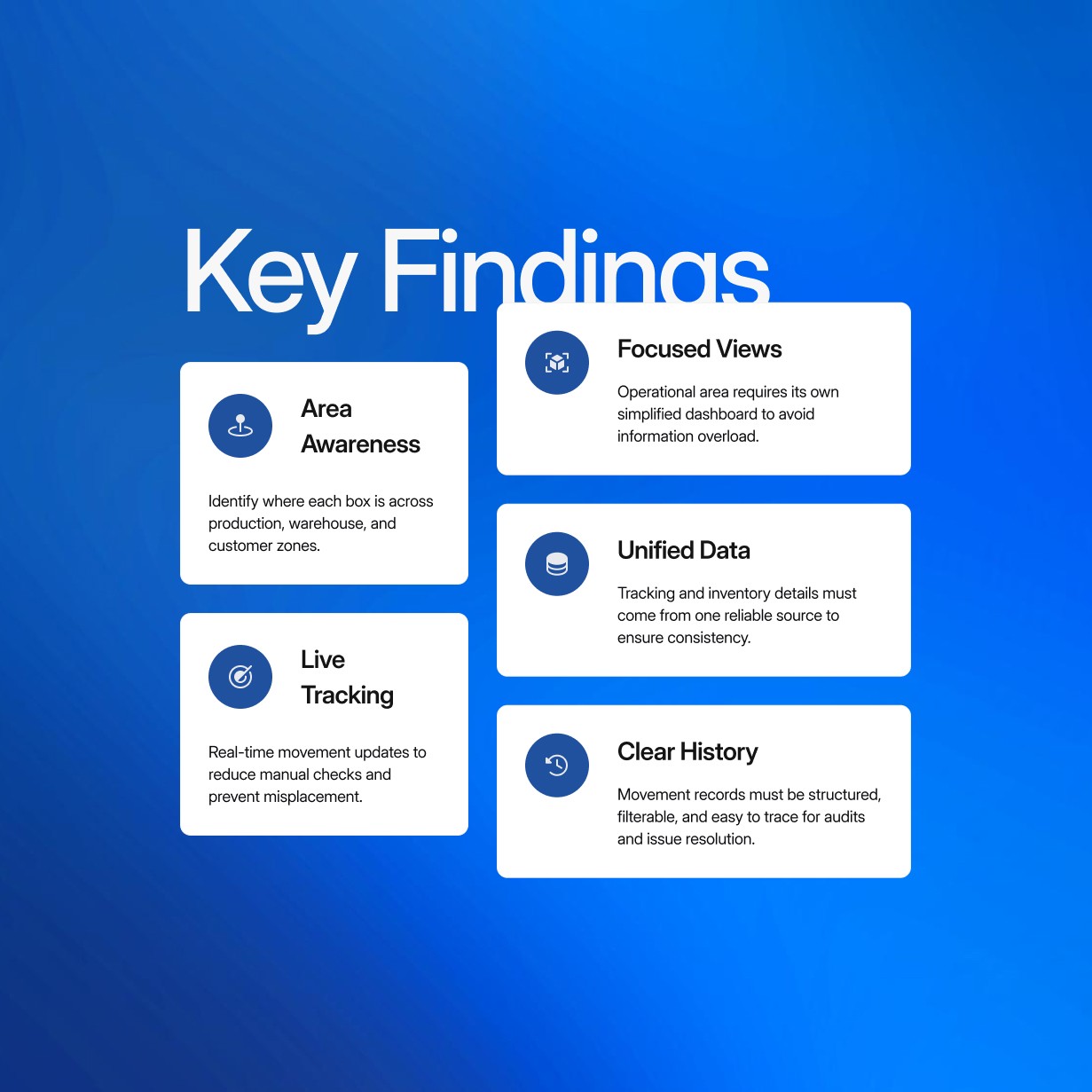

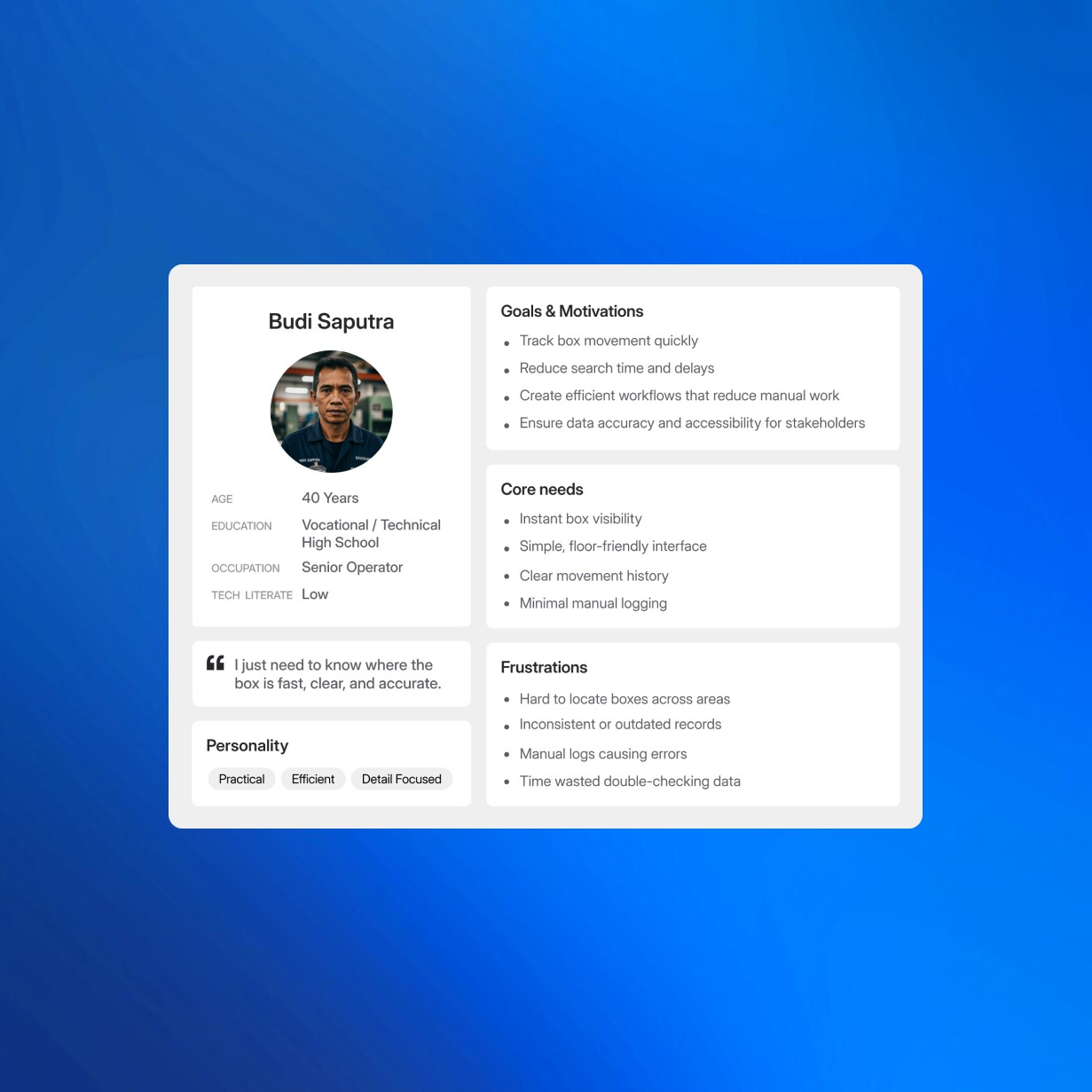

The existing box-tracking workflow relied heavily on manual recording, making it difficult to maintain accurate, real-time visibility across production, warehouse, and customer areas. Movements often went unrecorded or delayed, creating inconsistencies that slowed operations and complicated audits. Additionally, searching for specific boxes required navigating dispersed storage locations without a unified reference, leading to unnecessary time loss and higher risk of errors during daily operations.

The existing box-tracking workflow relied heavily on manual recording, making it difficult to maintain accurate, real-time visibility across production, warehouse, and customer areas. Movements often went unrecorded or delayed, creating inconsistencies that slowed operations and complicated audits. Additionally, searching for specific boxes required navigating dispersed storage locations without a unified reference, leading to unnecessary time loss and higher risk of errors during daily operations.

To enable this shift, the project introduces an integrated web and mobile platform that delivers real-time box status, location history, and essential operational workflows. This transition moves the organization toward a more data-driven ecosystem, improving coordination between teams and creating a stronger foundation for efficient and scalable inventory management.

To enable this shift, the project introduces an integrated web and mobile platform that delivers real-time box status, location history, and essential operational workflows. This transition moves the organization toward a more data-driven ecosystem, improving coordination between teams and creating a stronger foundation for efficient and scalable inventory management.

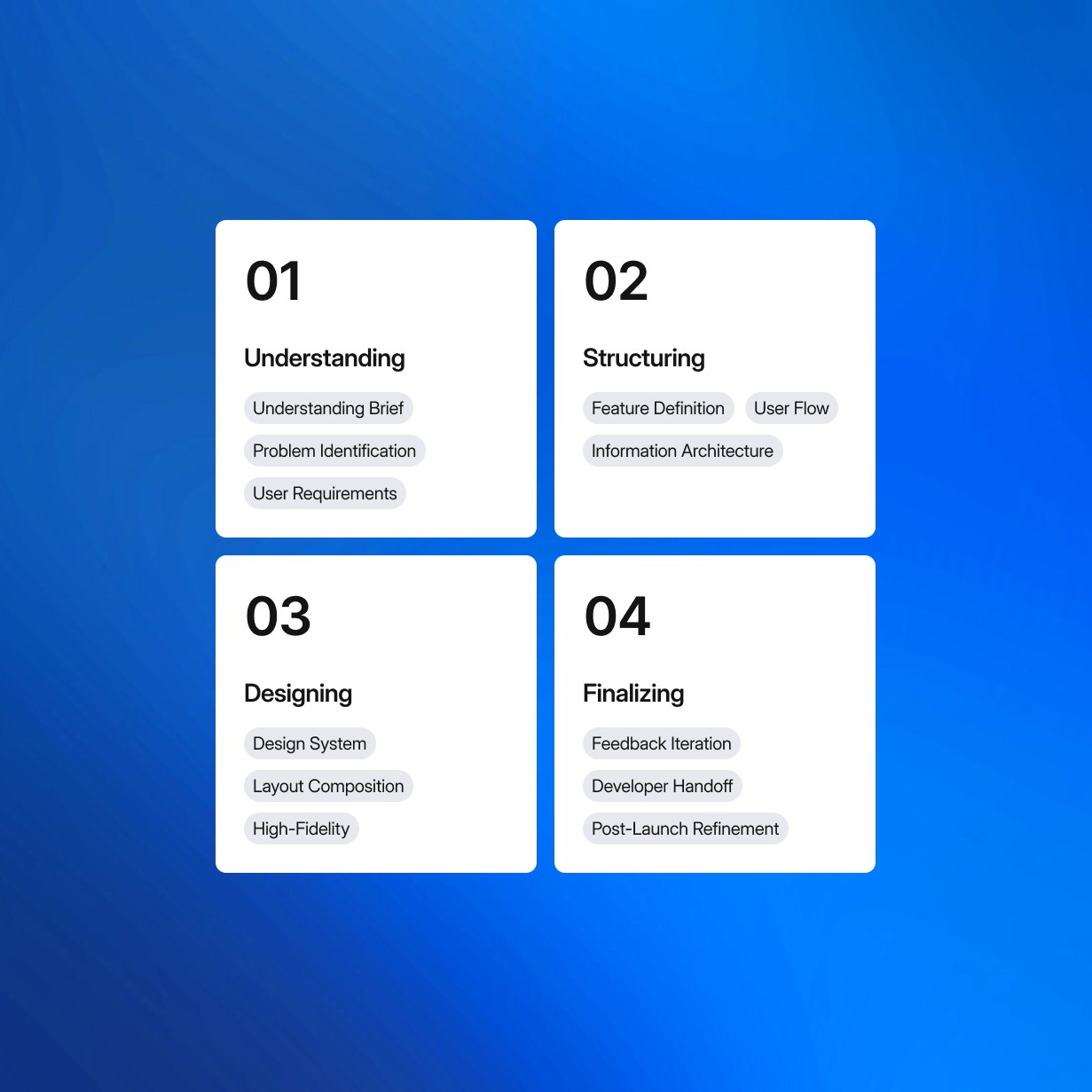

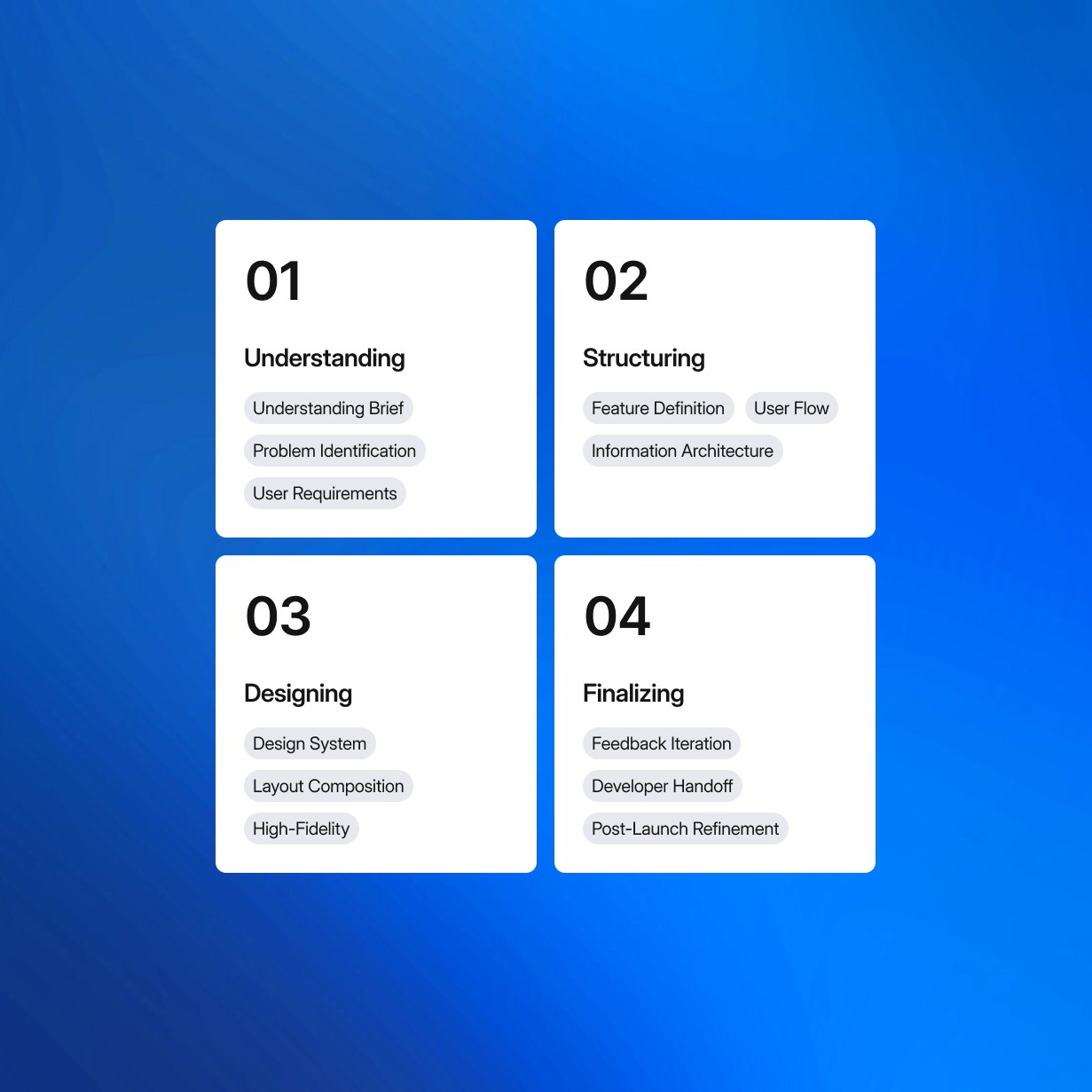

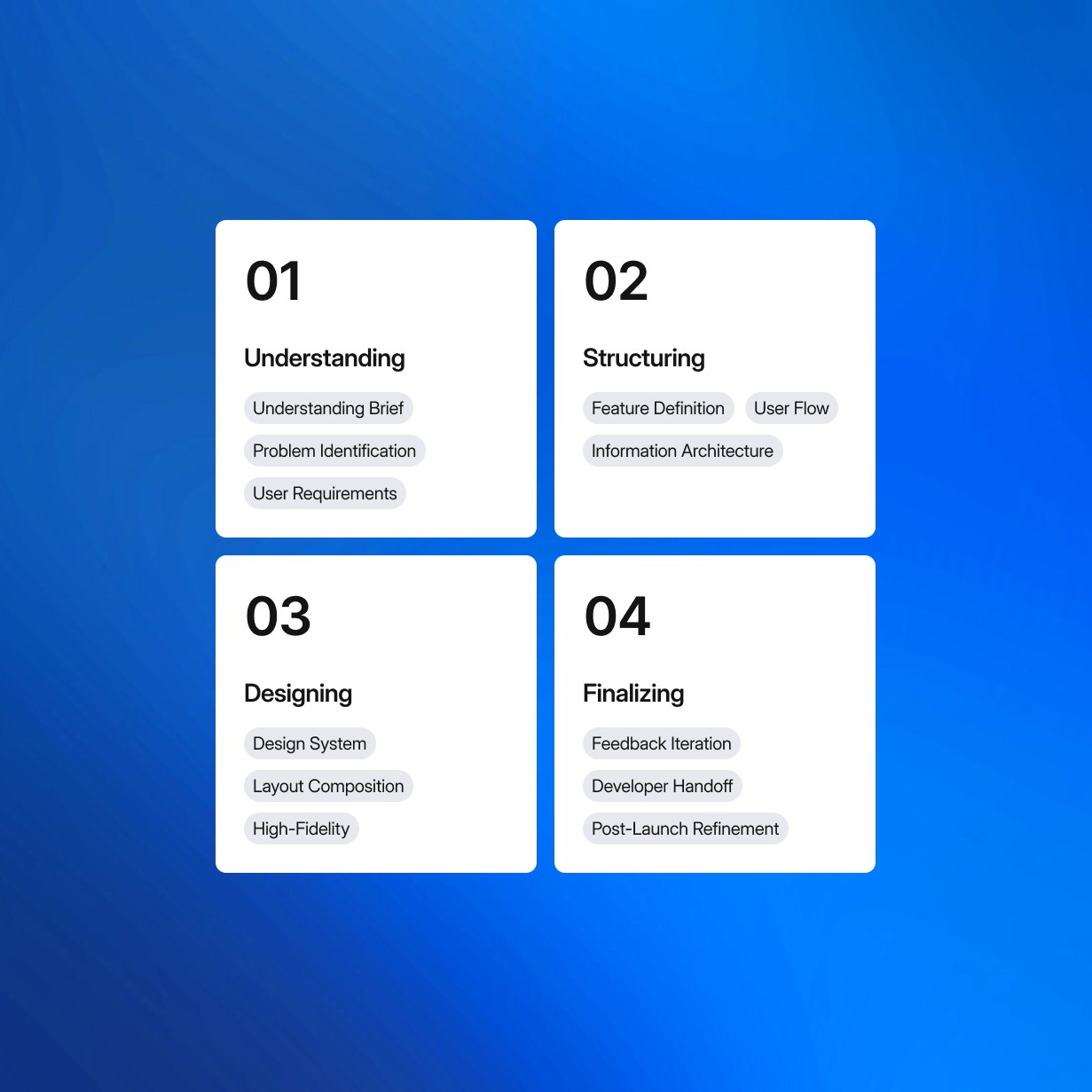

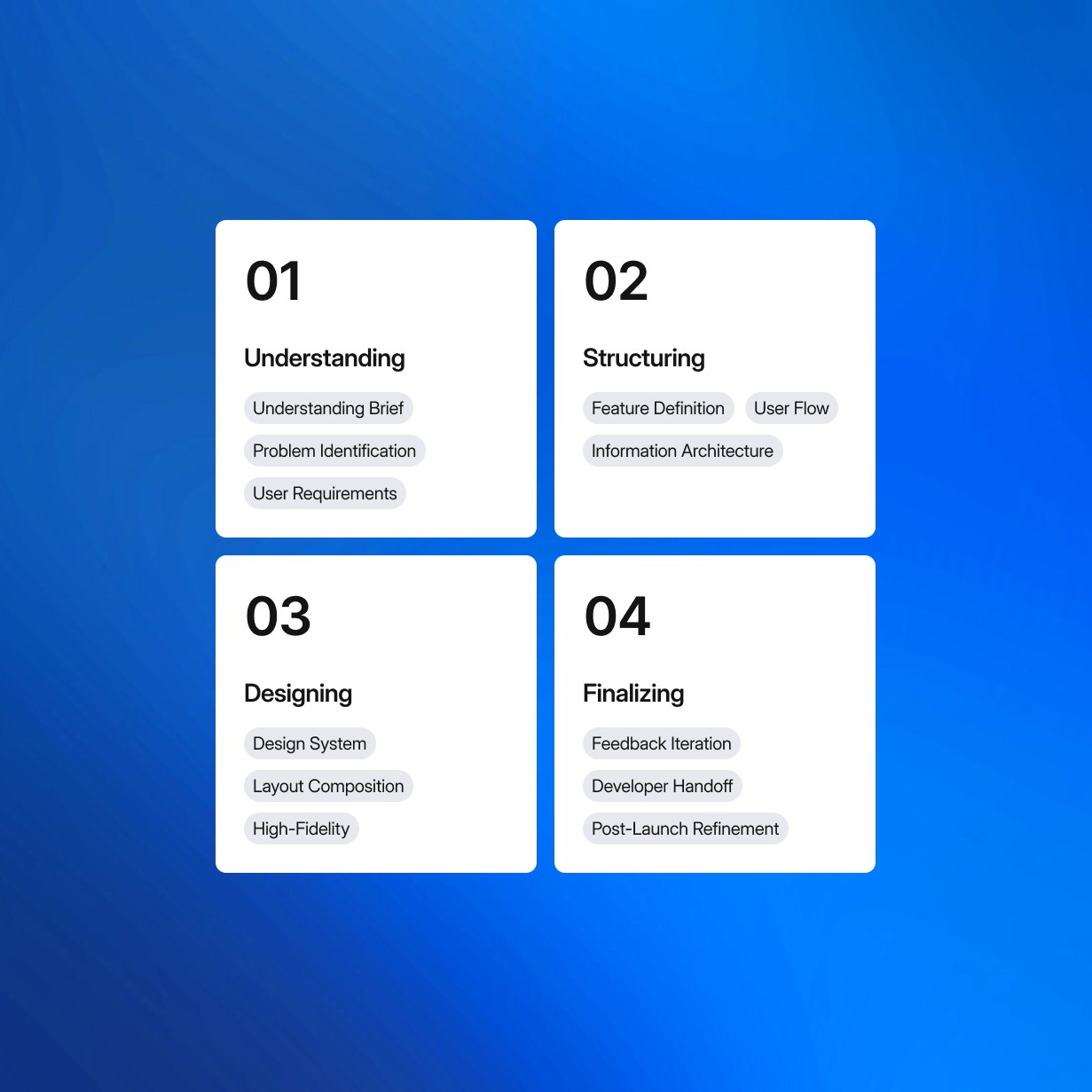

Design Proccess

Design Proccess

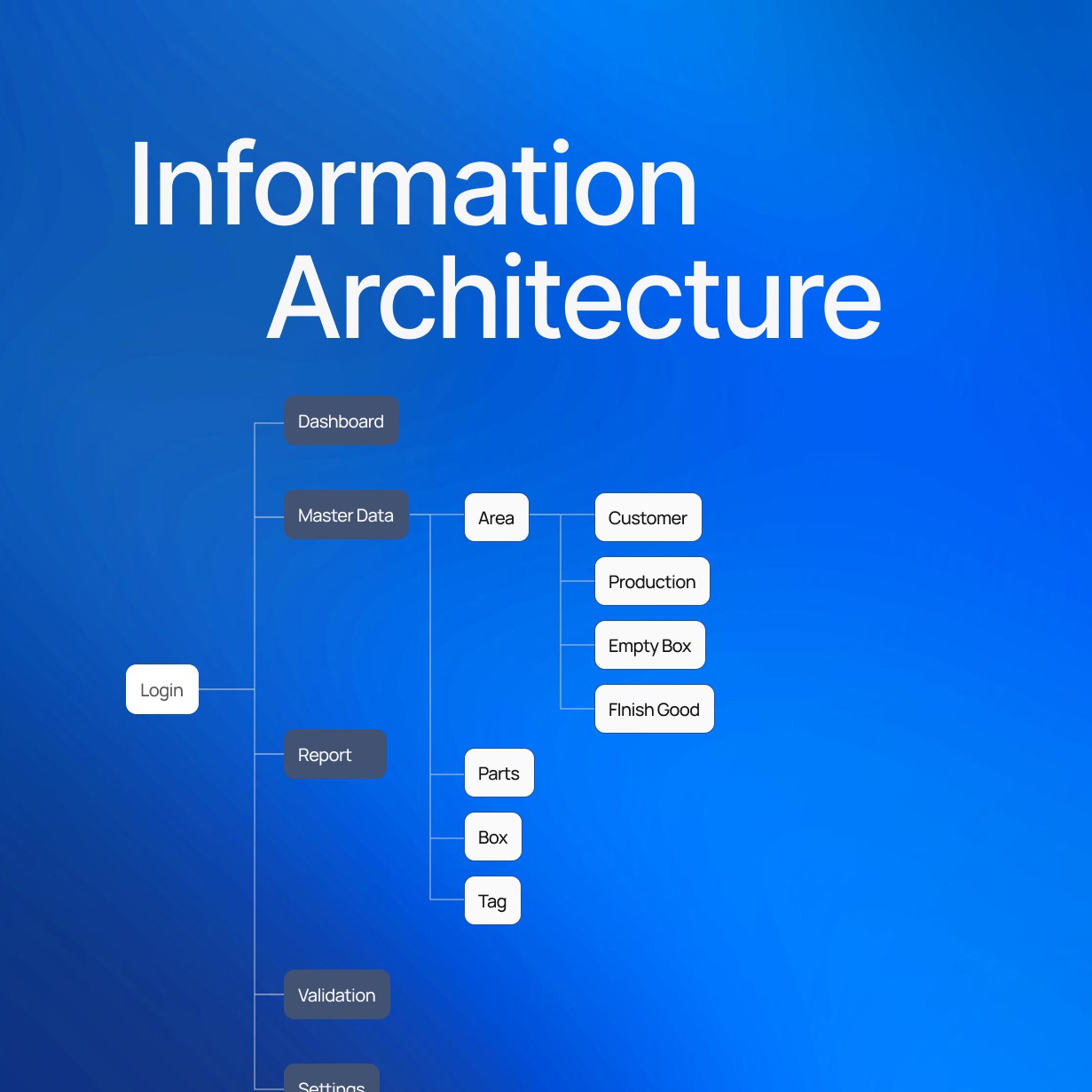

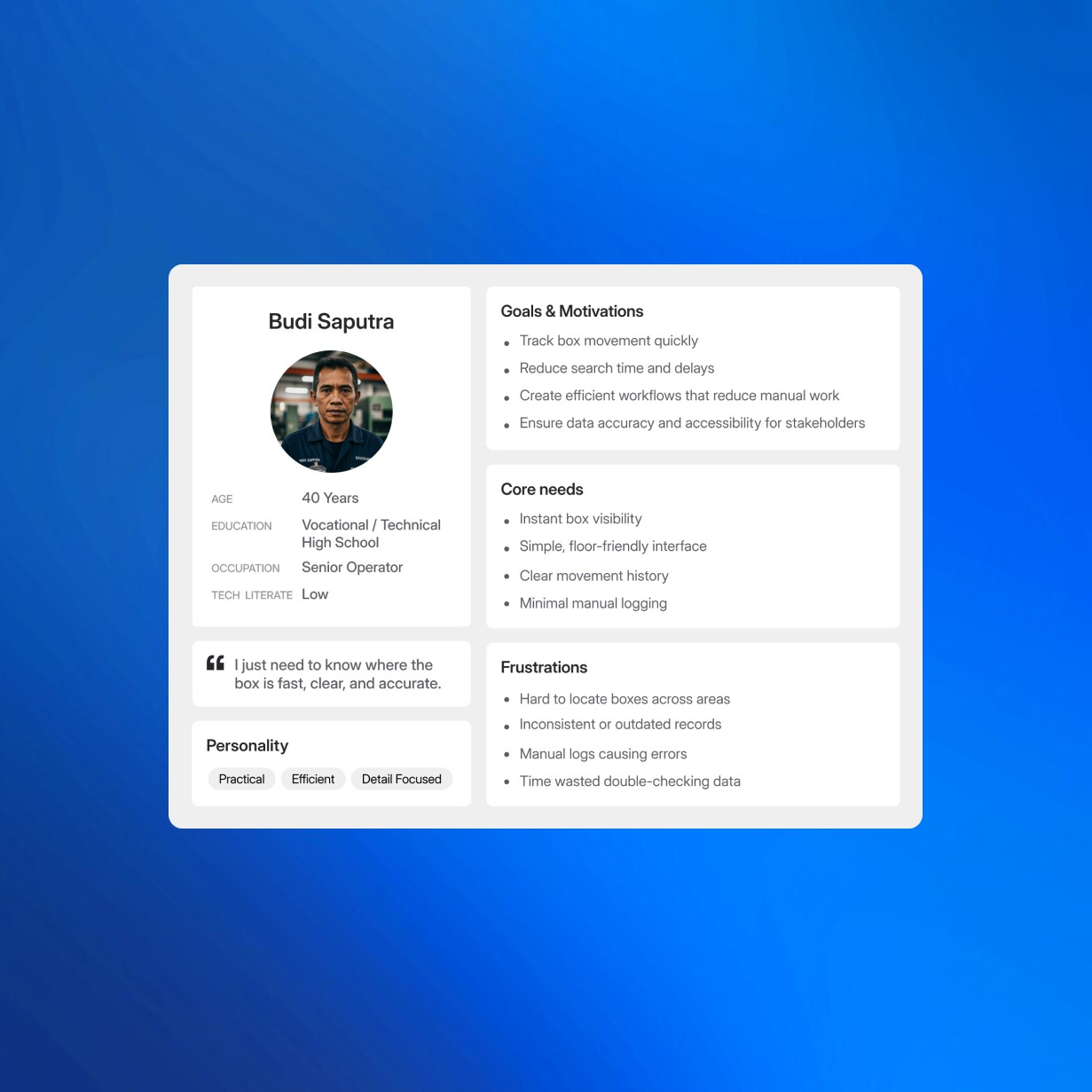

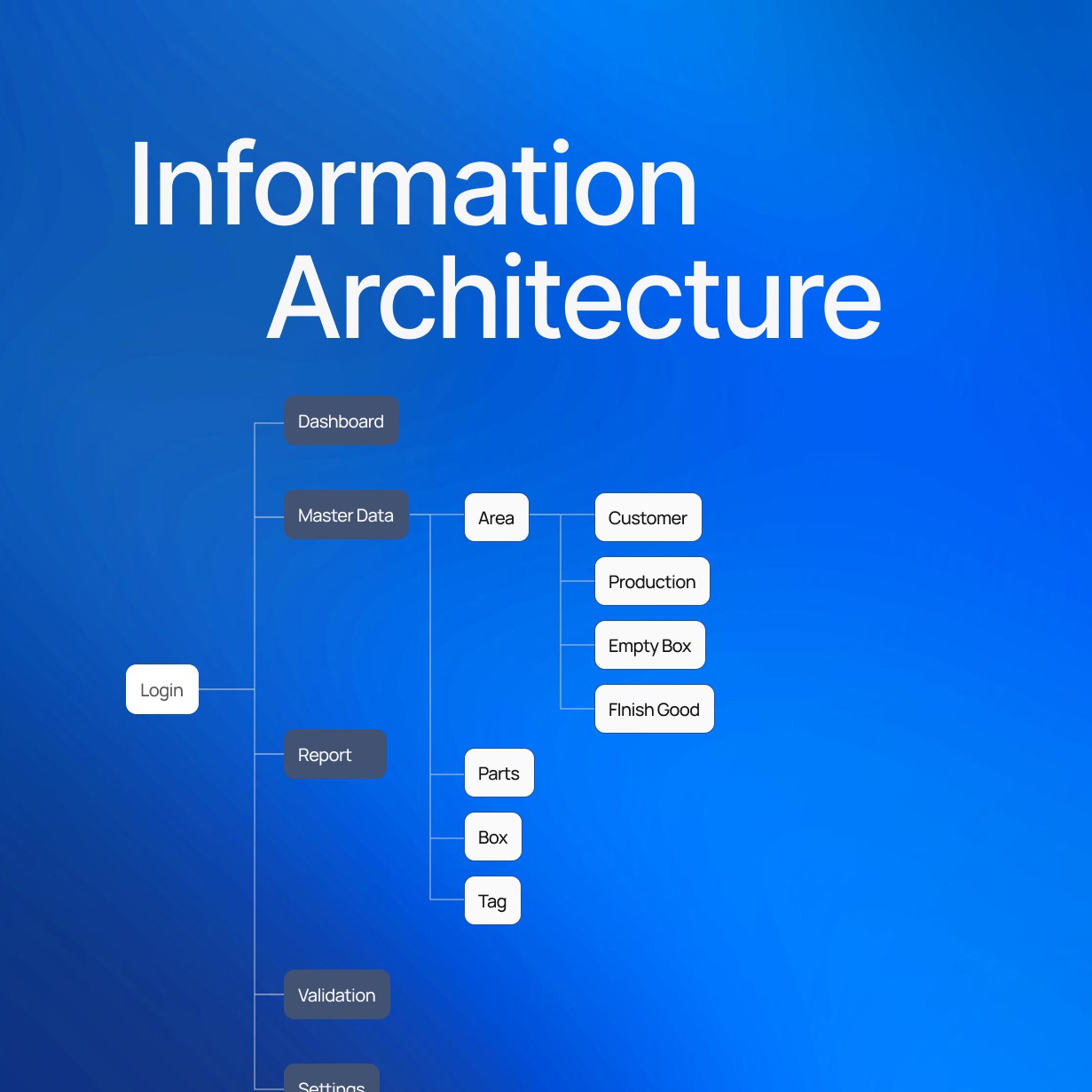

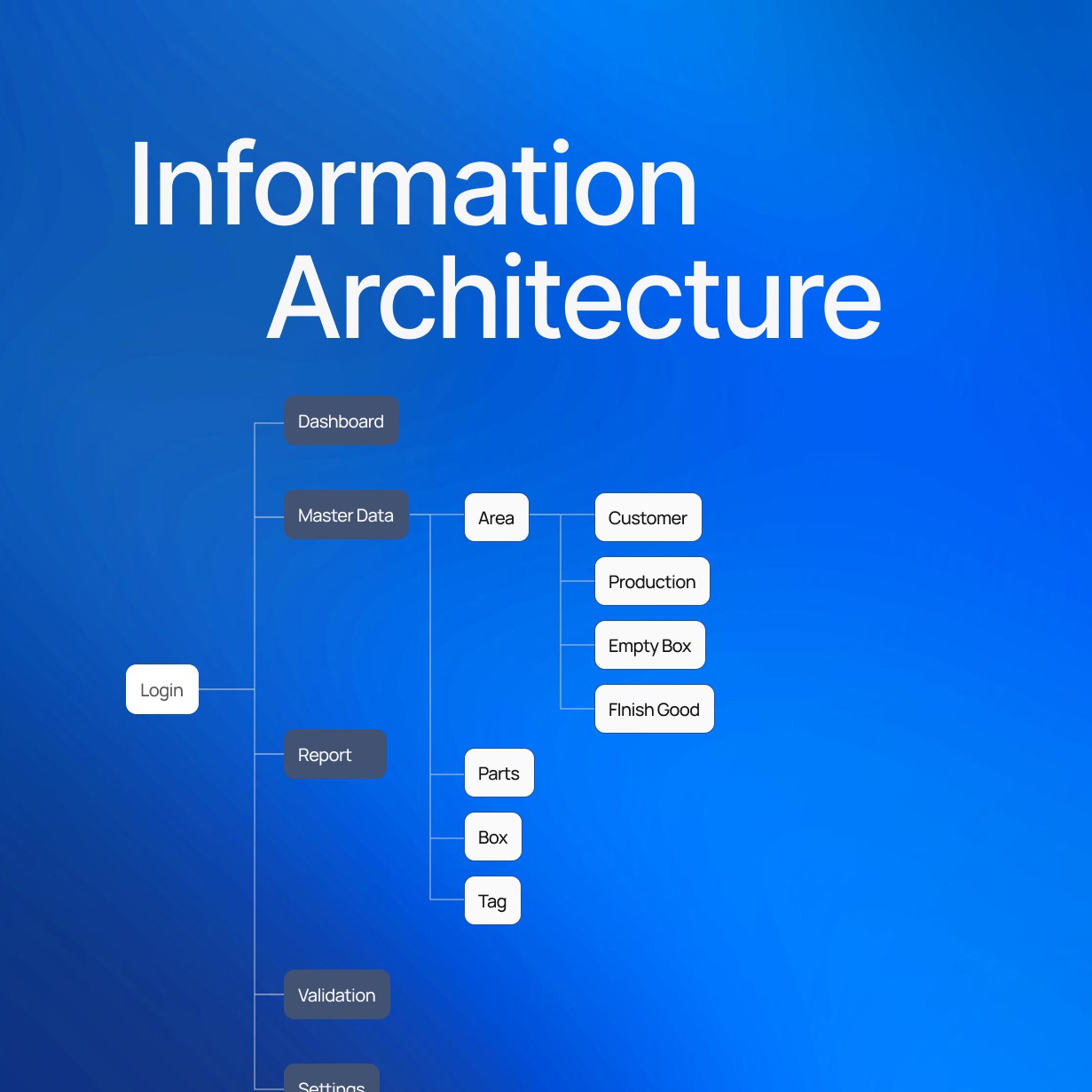

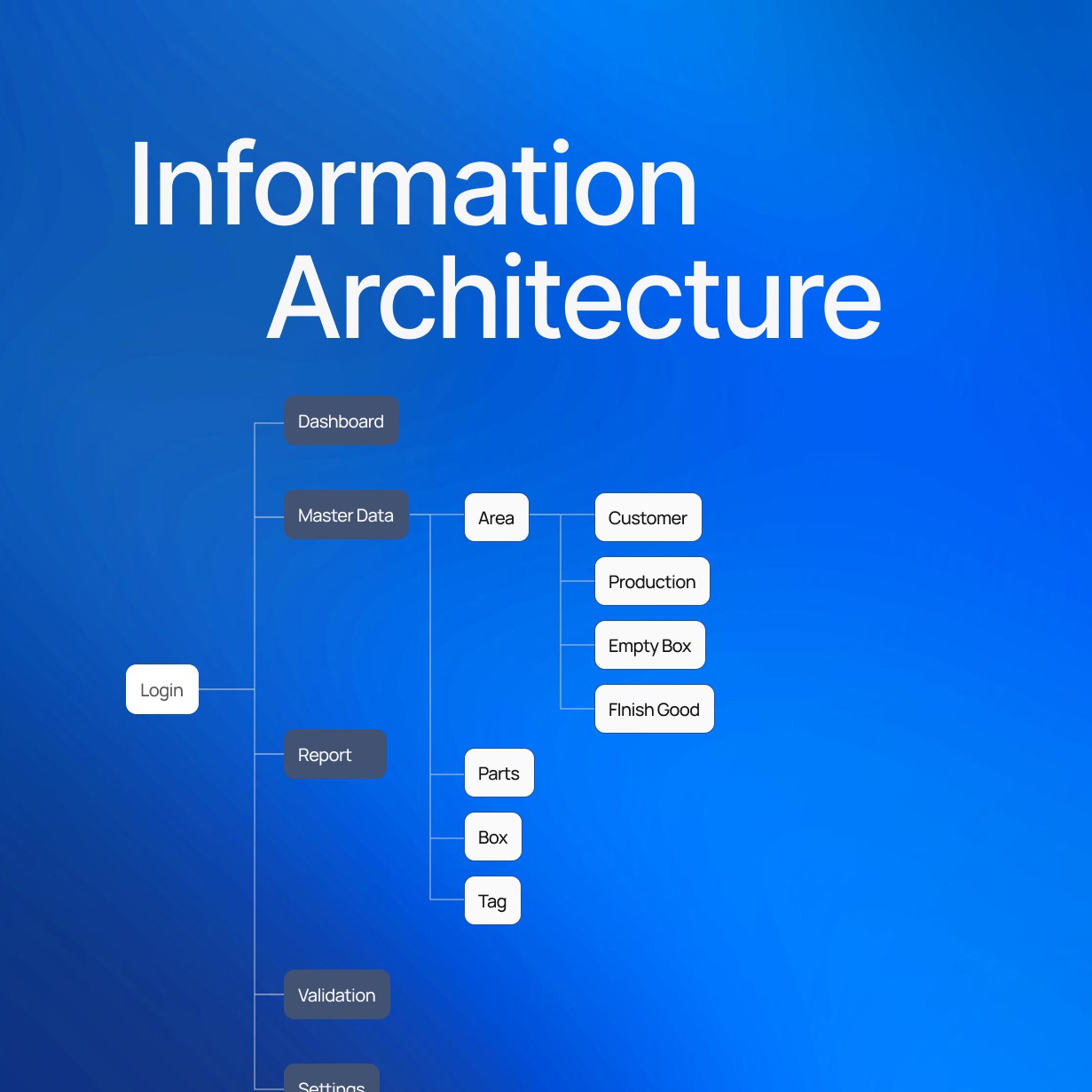

The design process relied on internal knowledge transfer rather than direct user research. Requirements were consolidated through discussions with the UI/UX lead, insights from the project manager, stakeholder inputs, and documented operational issues from PT. Astra Juoku Indonesia. These sources established a clear understanding of the existing box-tracking workflow, recurring inefficiencies, and the information hierarchy needed across production, warehouse, and customer areas.

The design process relied on internal knowledge transfer rather than direct user research. Requirements were consolidated through discussions with the UI/UX lead, insights from the project manager, stakeholder inputs, and documented operational issues from PT. Astra Juoku Indonesia. These sources established a clear understanding of the existing box-tracking workflow, recurring inefficiencies, and the information hierarchy needed across production, warehouse, and customer areas.

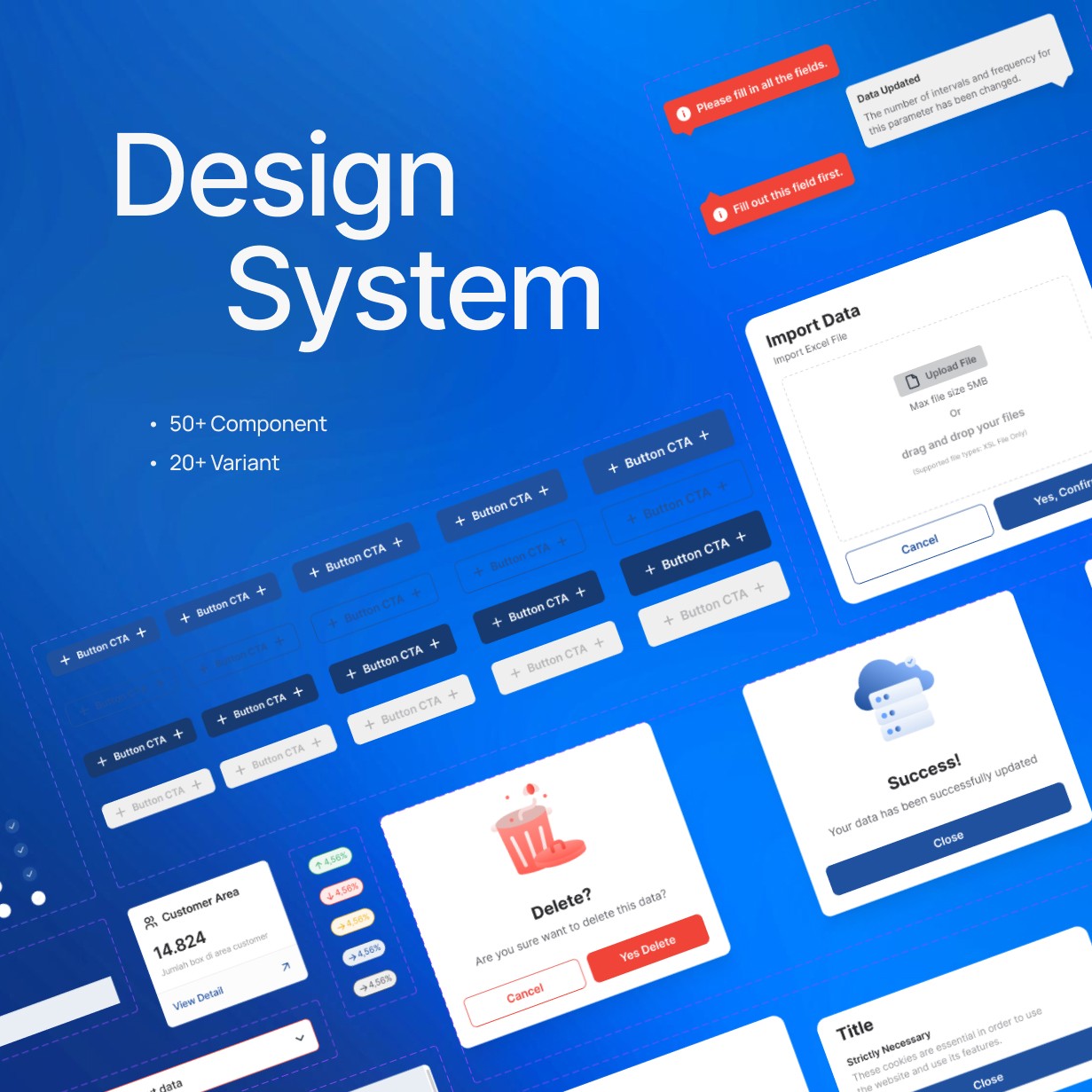

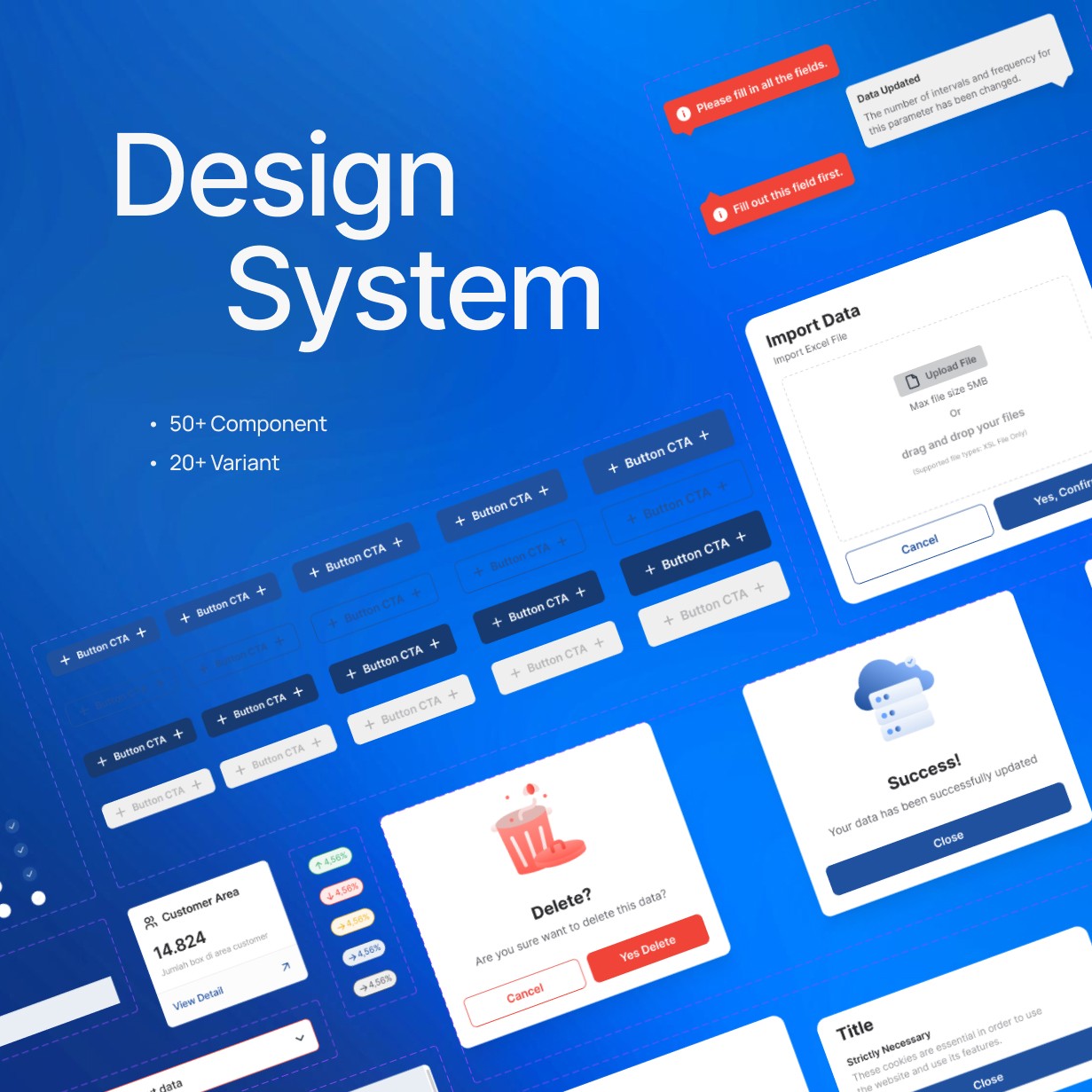

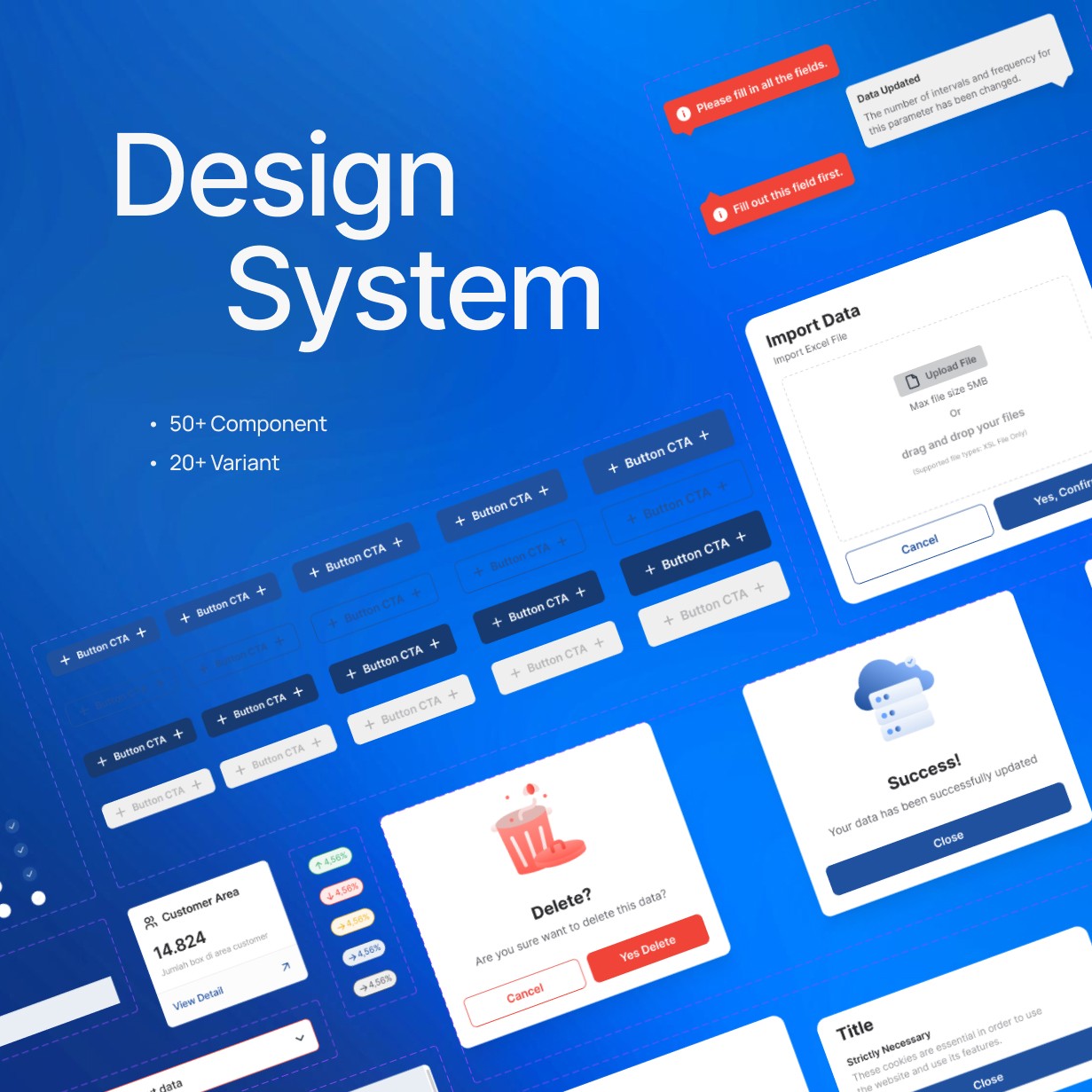

Using these insights, the system flow was translated into structured interfaces for both web and mobile platforms. Early wireframes focused on simplifying movement pathways, clarifying status visibility, and ensuring that scanning actions aligned with real factory procedures. Iterative refinement helped maintain consistency, reduce cognitive load, and shape a design that accurately reflected operational realities without requiring direct field observations.

Using these insights, the system flow was translated into structured interfaces for both web and mobile platforms. Early wireframes focused on simplifying movement pathways, clarifying status visibility, and ensuring that scanning actions aligned with real factory procedures. Iterative refinement helped maintain consistency, reduce cognitive load, and shape a design that accurately reflected operational realities without requiring direct field observations.

Outcome

Outcome

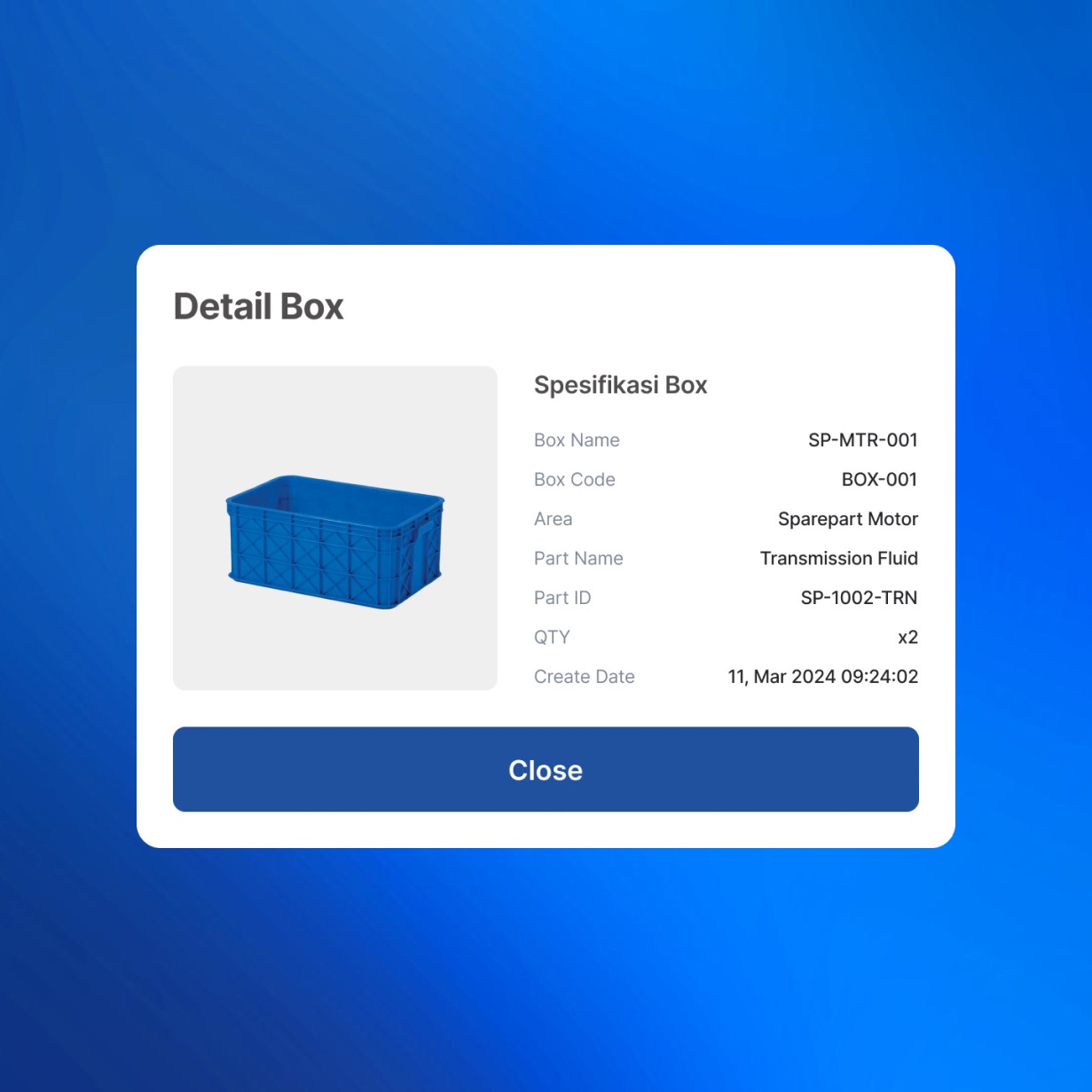

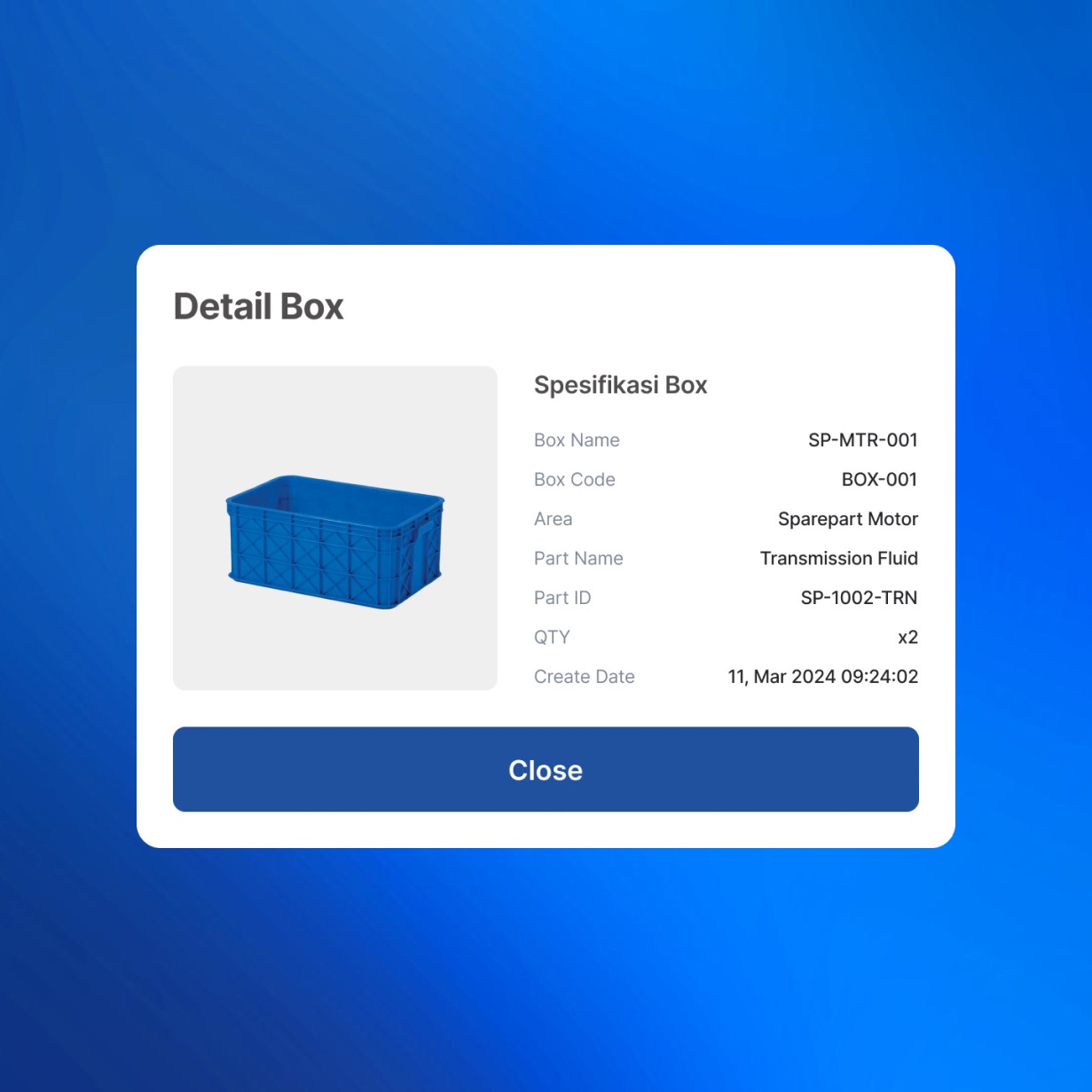

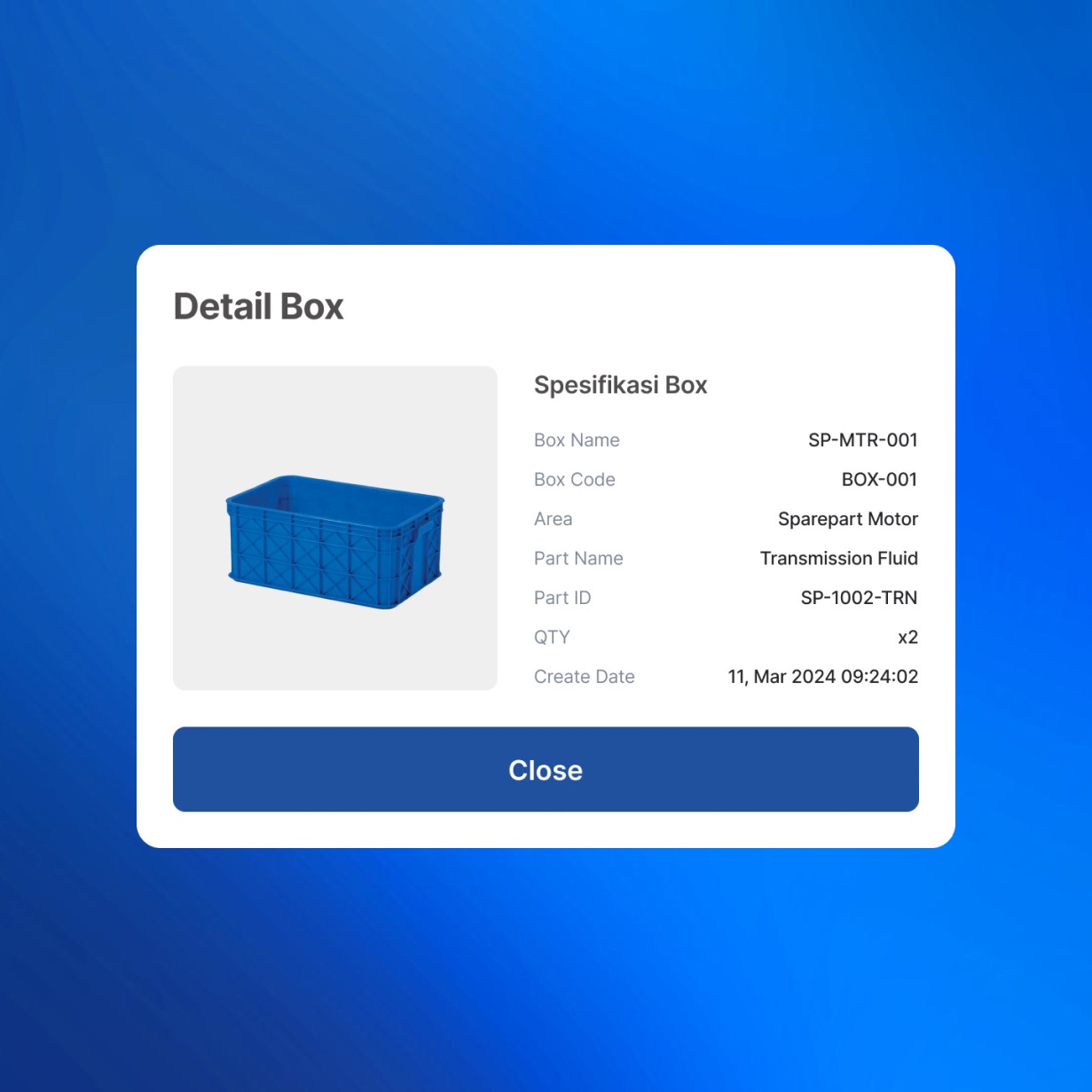

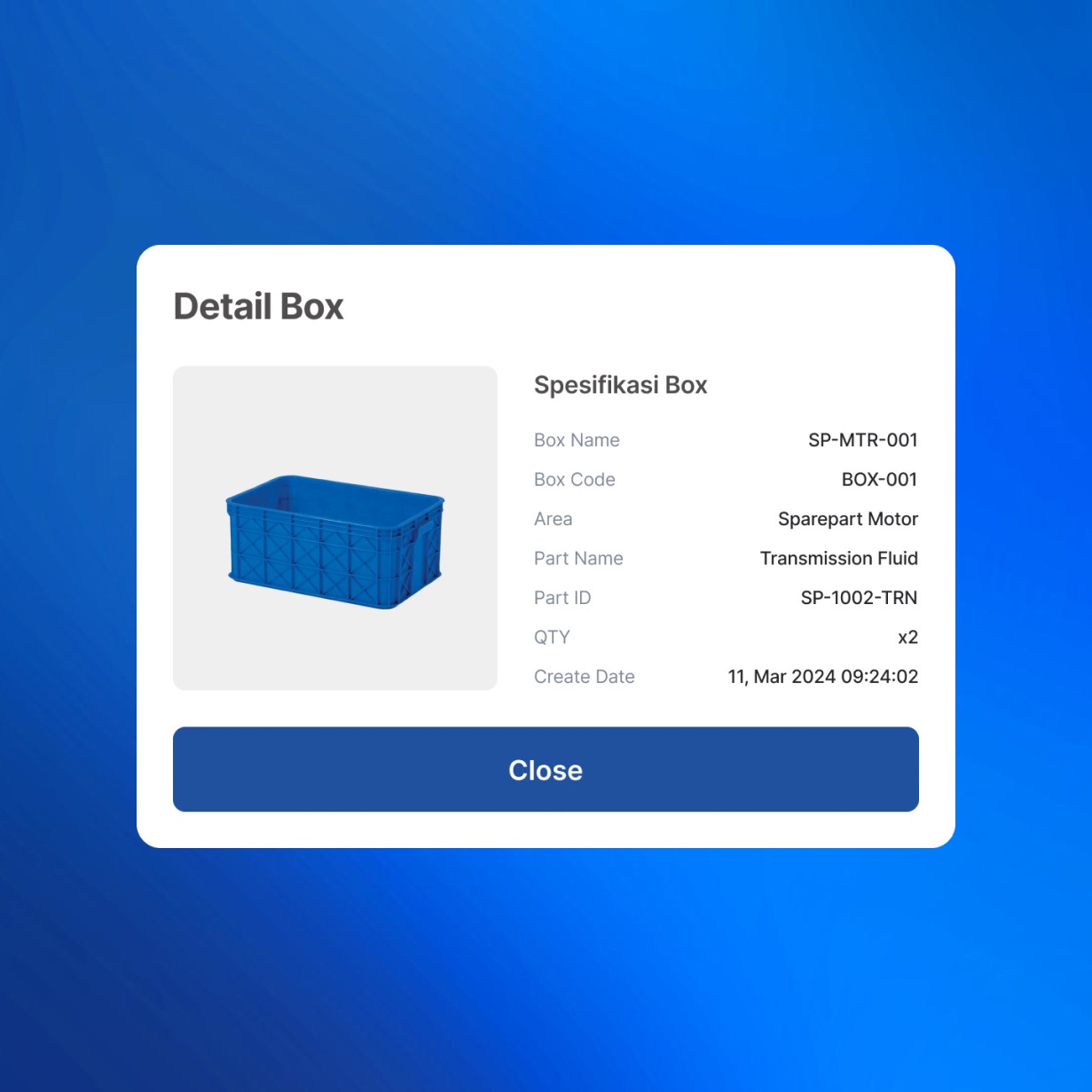

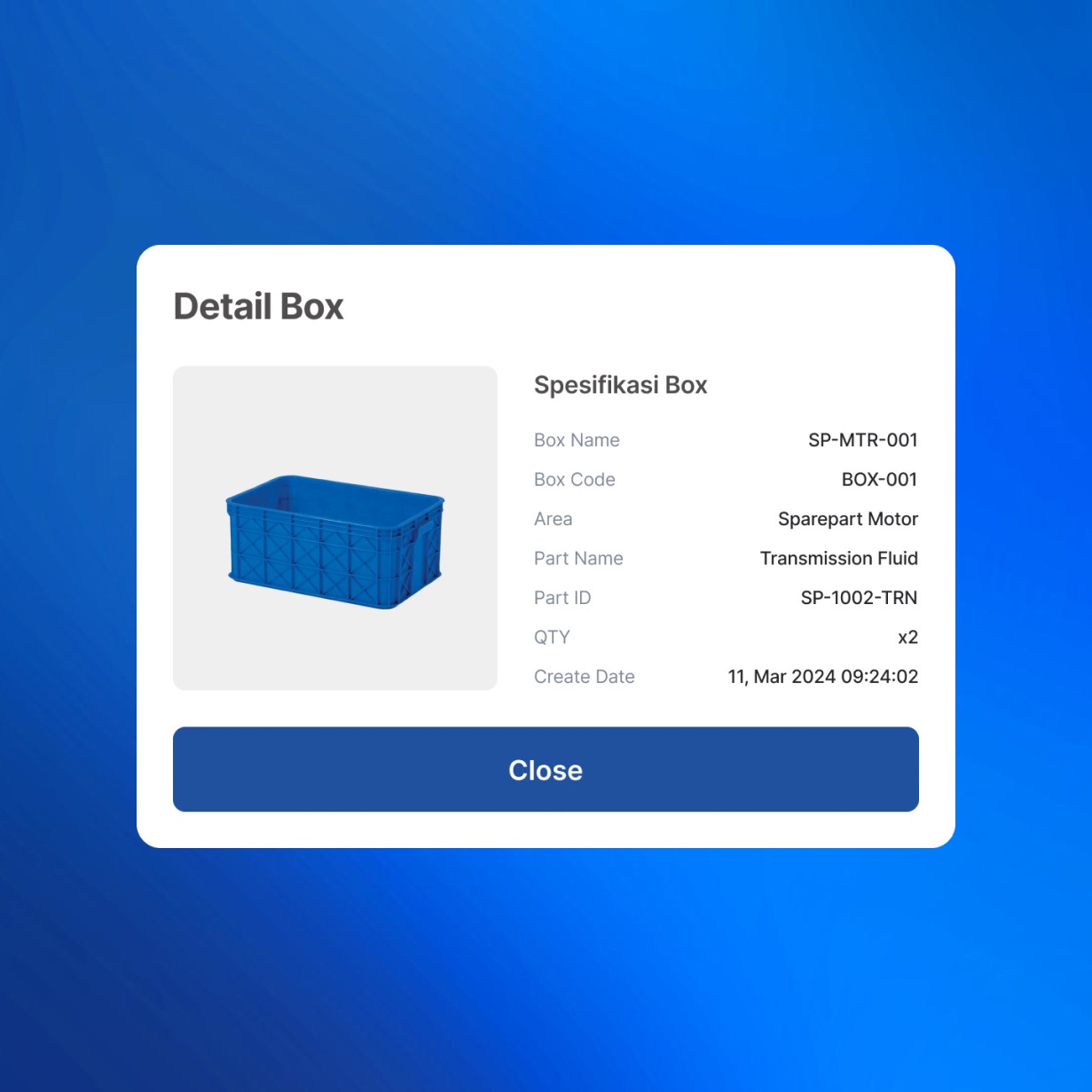

The final design brings structure and clarity to how box movements are represented across the system. Each interface aligns with actual factory flow, covering transitions from production to warehouse and customer areas, which helps the process feel more coherent and easy to follow. The information model is organized more effectively, allowing tracking points, identifiers, and movement states to connect smoothly across both web and mobile platforms.

The final design brings structure and clarity to how box movements are represented across the system. Each interface aligns with actual factory flow, covering transitions from production to warehouse and customer areas, which helps the process feel more coherent and easy to follow. The information model is organized more effectively, allowing tracking points, identifiers, and movement states to connect smoothly across both web and mobile platforms.

With a cleaner layout and consistent interaction patterns, the system presents information at the moment it is needed, reducing guesswork in daily operations. The scanning flow in the mobile app mirrors real on-site behavior more accurately, ensuring that every RFID action corresponds to a meaningful step in the workflow. These improvements result in a platform that feels more stable, predictable, and ready for long-term use.

With a cleaner layout and consistent interaction patterns, the system presents information at the moment it is needed, reducing guesswork in daily operations. The scanning flow in the mobile app mirrors real on-site behavior more accurately, ensuring that every RFID action corresponds to a meaningful step in the workflow. These improvements result in a platform that feels more stable, predictable, and ready for long-term use.

Impact

Impact

The design increases visibility into box locations and movement status by making the entire process more transparent. Clearer hierarchy and focused screens help reduce confusion and speed up interpretation in fast-paced factory environments. Well-defined states also make it easier to detect inconsistencies in the process before they escalate.

The design increases visibility into box locations and movement status by making the entire process more transparent. Clearer hierarchy and focused screens help reduce confusion and speed up interpretation in fast-paced factory environments. Well-defined states also make it easier to detect inconsistencies in the process before they escalate.

These refinements contribute to better operational accuracy by reducing unnecessary manual checks and strengthening confidence in the recorded data. By simplifying a complex workflow into a more intuitive visual structure, the system supports smoother coordination across production, warehouse, and distribution teams. Overall, the design enhancements demonstrate how a well-organized interface can directly improve efficiency in industrial settings.

These refinements contribute to better operational accuracy by reducing unnecessary manual checks and strengthening confidence in the recorded data. By simplifying a complex workflow into a more intuitive visual structure, the system supports smoother coordination across production, warehouse, and distribution teams. Overall, the design enhancements demonstrate how a well-organized interface can directly improve efficiency in industrial settings.

Reflection

Reflection

This project highlighted the importance of understanding the operational realities behind a system that relies heavily on repetitive and time-sensitive workflows. Even without direct user interviews, the combination of documented problems and internal team insights provided a strong foundation for identifying the core design needs.

This project highlighted the importance of understanding the operational realities behind a system that relies heavily on repetitive and time-sensitive workflows. Even without direct user interviews, the combination of documented problems and internal team insights provided a strong foundation for identifying the core design needs.

It also reinforced the value of simplifying complexity without altering the meaning of the process itself. Mapping a multi-step physical journey into a digital environment required careful attention to how information appears, transitions, and connects. These insights continue to inform how industrial tools can be designed with clarity, alignment, and long-term adaptability in mind.

It also reinforced the value of simplifying complexity without altering the meaning of the process itself. Mapping a multi-step physical journey into a digital environment required careful attention to how information appears, transitions, and connects. These insights continue to inform how industrial tools can be designed with clarity, alignment, and long-term adaptability in mind.